Description

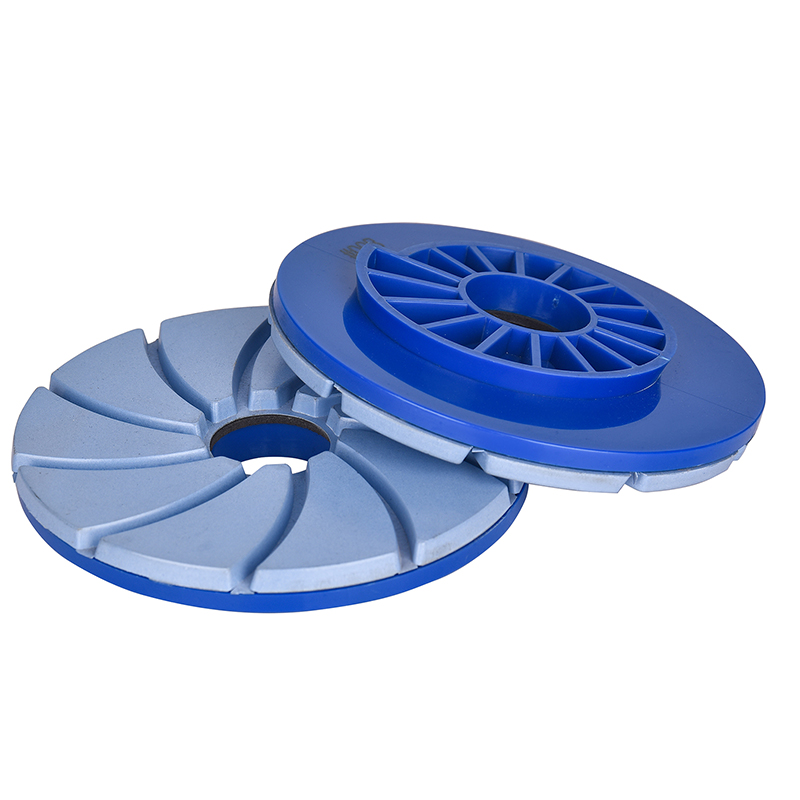

Resin bond diamond grinding disc is used for fine polishing granite, marble and other stone slabs on automatic polishing lines or manual polishing machines. It is one of the best resin grinding disc in the market. The distance between diamond segments and uniformity distribution prevent slabs from dust and avoid scratching. The overall polishing effect can be reached easily if it is used in conjunction with our metal bond diamond grinding disc for initial grinding. Resin bond diamond grinding discs are usually used after metal bond diamond grinding disc. Resin bonded diamond grinding discs are efficient tools widely used in the stone industry for fine polishing of granite, marble and various other stone slabs. Compatible with automatic polishing lines and manual polishing machines, these polishing discs provide multiple applications in different polishing systems. One of the key factors that sets resin bond diamond grinding discs apart from others on the market is their superior performance and quality. These grinding discs are considered as one of the best resin grinding discs due to their superior features and functionality. The diamond segments on the disc are carefully spaced to ensure an optimal distance between them. This design feature, combined with an even distribution, plays an important role in preventing the accumulation of dust particles during polishing. As such, it helps to keep the surface clean and free of debris, thereby increasing the overall efficiency and effectiveness of the polishing operation. Additionally, the well-designed spacing and distribution of the diamond tips helps to avoid scratching or damaging the slab. This feature is critical to achieving a flawless professional-grade finish on polished surfaces. For best results, resin bonded diamond discs and metal bonded diamond discs are recommended for the initial grinding phase. Metal bonded discs are great for more aggressive grinding and leveling of stone surfaces, while resin bonded discs excel at providing a final finish. The combination of resin and metal bonded discs provides a comprehensive polishing solution, ensuring a smooth, glossy finish to the highest industry standards. By using the discs sequentially, starting with metal bond discs and then resin bond discs, an overall finish can easily be achieved. In conclusion, resin bond diamond discs are versatile and quality tools for fine polishing stone slabs. From preventing dust buildup and avoiding scratches to providing superior polishing results, these polishing discs are renowned in the market for their superior performance and unrivaled quality. As a result, they deliver outstanding results in both automatic and manual polishing applications and are trusted by stone industry professionals.Production Process

Specifications

| Type | Grinding disc |

| Application | For marble, granite and other stone slabs grinding and polishing |

| Size | 8’’(200mm), 10’’(250mm) |

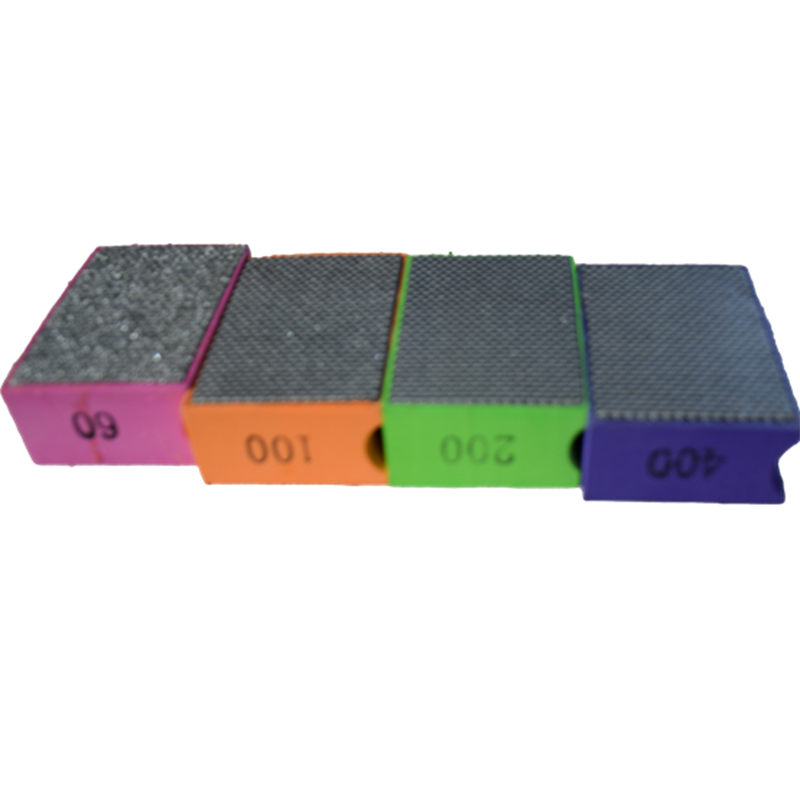

| Grit | 500#800#1500#2000#3000# |

| Special specifications are available upon to customer’s requirement | |

Features

1.Good sharpness with long lifespan, fast polishing with high glossiness. 2.Competitive price and superior quality. 3.Other grits and sizes can be offered as requested. 4.Different formulas of segment according to the hardness of stone slabs. 5.Common design same as other suppliers, easy for workers to accept and handle. 6.Supply the whole set of grinding and polishing tools from rough grinding to fine polishing. 7.Support OEM and ODM service. Special specification can be available upon requirement.