Premium Diamond Brush Unveiled in Frankfurt Sparks Interest Among Professionals

By:Admin

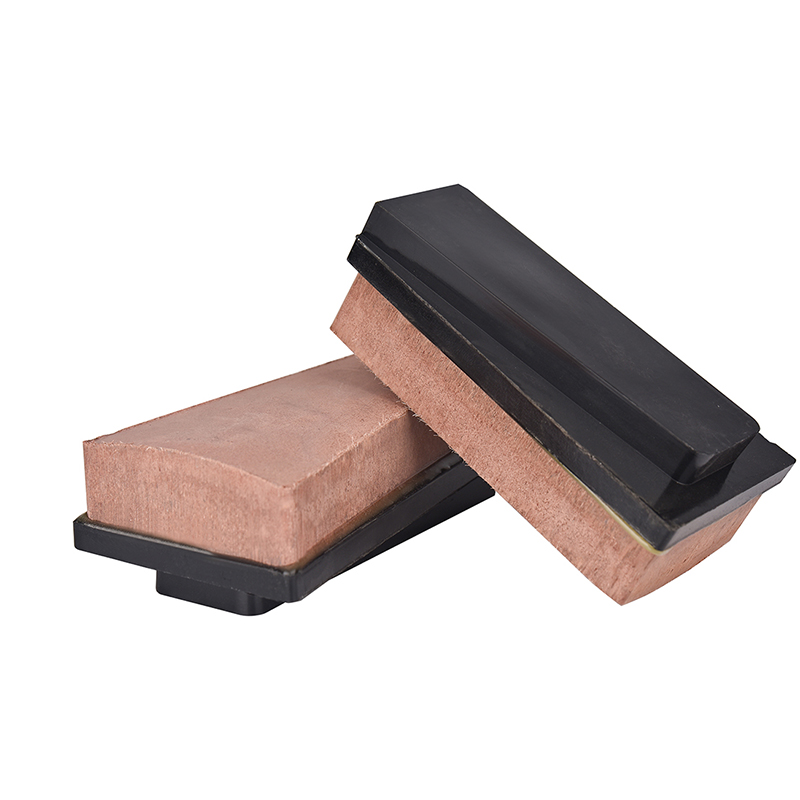

Frankfurt Brush Innovations, a leading player in the diamond brush industry, has introduced a groundbreaking product that promises to revolutionize stone and concrete polishing procedures. The company's latest offering, which remains nameless as per the news content, combines cutting-edge technology with superior build quality to provide users with exceptional performance and durability.

This state-of-the-art diamond brush is manufactured using the highest quality materials, ensuring precise and consistent results every time. The advanced manufacturing process ensures that each brush maintains its original shape and functions at optimal efficiency for extended periods. Additionally, the brush's design allows for easy installation and compatibility with a wide range of equipment, making it a versatile solution for various applications.

One of the standout features of this cutting-edge product is its outstanding polishing capabilities. The diamond-infused bristles work in perfect synergy to deliver a flawless finish, removing any visible imperfections from the surface. This ensures that each project achieves a mirror-like shine, surpassing industry standards and leaving a lasting impression on clients and users alike.

The durability and longevity of the brush are unparalleled thanks to the innovative composition of the diamond-infused bristles. This unique blend of materials ensures that the brush maintains its effectiveness, even under intense wear and tear. This longevity translates into savings for users as it reduces the frequency of brush replacement, thus optimizing operational efficiency and minimizing associated costs.

The company's commitment to research and development is evident in this breakthrough product. Frankfurt Brush Innovations has invested significant resources into understanding market demands and tailoring their solutions accordingly. Through continuous testing and improvement, they have managed to create a diamond brush that outperforms competitors in terms of efficiency, longevity, and overall value for money.

Moreover, customers can rely on Frankfurt Brush Innovations for unparalleled customer service and technical support. The company's team of experienced professionals is readily available to address any queries or concerns, providing guidance and recommendations for optimal usage of their products. This dedication to customer satisfaction has made the brand a trusted name in the industry and has earned them a loyal customer base.

With this groundbreaking product, Frankfurt Brush Innovations has set a new standard in diamond brush technology. By combining state-of-the-art materials and rigorous manufacturing processes, the company has created a product that is not only highly effective but also cost-efficient. Their commitment to innovation and customer satisfaction cements their position as a market leader in the diamond brush industry.

In conclusion, Frankfurt Brush Innovations has introduced an exceptional diamond brush that is set to transform stone and concrete polishing procedures. The nameless product represents a significant leap forward in technological advancements, offering users unmatched performance, longevity, and value for money. With their customer-centric approach and commitment to innovation, Frankfurt Brush Innovations continues to establish themselves as a frontrunner in the industry.

Company News & Blog

Advanced Resin Bond Diamond Polishing Pads: The Latest Innovation in Surface Polishing" can be rewritten to "Revolutionary Resin Bond Diamond Polishing Pads: A Breakthrough in Surface Polishing Technology.

Resin Bond Diamond Polishing Pad - The Ultimate Solution for PolishingPolishing is a crucial process in the manufacturing industry as it enhances the beauty and durability of the final product. Over the years, various polishing materials have been in existence and have gained popularity, but none can match the effectiveness of resin bond diamond polishing pads. Resin bond diamond polishing pads are an excellent choice for polishing a wide range of surfaces, including concrete, marble, and granite, among others. Resin bond diamond polishing pads are designed to offer an unparalleled polishing experience. They are made of diamond powder, which is uniformly distributed over the pad's surface. This results in a smooth, even, and consistent finish, even on rough surfaces. Resin bond diamond polishing pads are available in different shapes and grits, making them suitable for various applications, including wet or dry polishing. The higher the grit number, the smoother the surface will become. Many companies specialize in the production of resin bond diamond polishing pads, but only a few have been able to provide high-quality and reliable products. One such company is (need remove brand name). With years of experience in manufacturing and distribution, (need remove brand name) has become a leading provider of a wide variety of products that cater to different needs in the industry. (need remove brand name) is committed to providing its customers with superior products that guarantee them the best results possible. The company's resin bond diamond polishing pads are designed for exceptional performance, durability, and affordability. The pads are made using state-of-the-art production techniques, ensuring that they can withstand the toughest conditions. One of the most significant benefits of using (need remove brand name) resin bond diamond polishing pads is their ability to minimize scratching and scuffing. The resin bond holds the diamond in place, preventing them from falling out, thereby minimizing surface damage. This ensures a clean and professional look, which is vital in the manufacturing industry. (need remove brand name) resin bond diamond polishing pads offer a smooth finish, which means that fewer finishes are required, saving time and labor costs significantly.Another critical advantage of using (need remove brand name) resin bond diamond polishing pads is the versatility they offer. They can be used on different surfaces, such as marble, granite, concrete, and engineered stone, among others. The company offers a variety of grits to meet the different needs of its customers. Furthermore, (need remove brand name) resin bond diamond polishing pads can be used in both dry and wet conditions, providing flexibility and convenience.(need remove brand name) resin bond diamond polishing pads are available in various sizes, shapes, and forms, making them suitable for different polishing machines. The pads are user-friendly, meaning that anyone can use them, thus saving on training costs.In conclusion, (need remove brand name) resin bond diamond polishing pads are the ultimate solution for individuals and companies in need of high-quality, efficient, and cost-effective polishing materials. (need remove brand name) prides itself on providing exceptional products and services that meet and exceed its customers' expectations. The company also offers excellent after-sales services, ensuring that its clients get maximum value from the products they purchase. Whether you're a professional or DIYer in the manufacturing industry, you can't go wrong with (need remove brand name) resin bond diamond polishing pads. With their versatility, durability, and affordability, these pads set the standard for the best polishing materials in the market. Get your hands on (need remove brand name) resin bond diamond polishing pads and experience the difference in your polishing process.

High-Performance Metal Bond Fickert: The Ideal Solution for Granite Polishing in China

China Diamond Metal Bond Fickert for Granite Offers Revolutionary Grinding SolutionChinese manufacturer {} has recently launched an innovative metal bond fickert for granite, which is set to revolutionize the grinding and polishing processes for the stone industry. The new product is designed to offer exceptional performance, longevity, and versatility, providing a superior alternative to traditional abrasives.The China Diamond Metal Bond Fickert for Granite features an advanced diamond coating that achieves a highly efficient grinding result with minimal material wastage. It has been engineered using advanced metal bond technology, which offers superior resilience, wear resistance, and durability compared to other abrasives in the market. Diamond grit sizes from 36 to 8000 are available for different applications, providing optimal grinding performance for various surfaces.The fickert is available in different dimensions and shapes, enabling users to customize the grinding process to fit their particular needs. This versatility means users can achieve a range of finishes, from coarse grinding to mirror polishing, in a single process. The product is also transportable across multiple machines, further increasing efficiency and reducing production time.Due to its advanced composition, the China Diamond Metal Bond Fickert for Granite has a longer service life compared to other abrasives. This feature means the fickert remains highly efficient for an extended period, reducing production downtime and repair costs. The product also improves the work environment for operators by reducing noise pollution and dust emissions during the grinding and polishing process.The Chinese manufacturer responsible for the China Diamond Metal Bond Fickert for Granite prides itself on being at the forefront of technological advancements in producing diamond tools. As one of the leading manufacturers and suppliers in China, the company has an extensive research and development team dedicated to crafting innovative solutions for the stone industry. Their focus on high-quality and excellent performance has made them a trusted partner for customers worldwide.According to the representative for the Chinese manufacturer, "We're excited to introduce the China Diamond Metal Bond Fickert for Granite to the market. It is a revolutionary abrasive that brings a range of benefits to the industry. It is highly efficient in grinding and polishing, reducing production time and material wastage. It is also customizable, versatile, and designed for longevity, and we believe it will be very popular among our customers."The China Diamond Metal Bond Fickert for Granite is the latest innovation in diamond tools from the Chinese manufacturer. With a reputation for excellent quality and performance, the new product is set to disrupt the traditional abrasives market and set the bar for future solutions.In conclusion, the China Diamond Metal Bond Fickert for Granite offers a revolutionary solution for the stone industry. Its advanced composition, superior resilience, and longevity make it the ideal tool for grinding and polishing granite surfaces. The product's versatility, long service life, and excellent performance are sure to make it a popular choice among industry professionals worldwide. The Chinese manufacturer continues to demonstrate its commitment to innovation and excellence, and this newest product is a testament to that.

What Are Satellite Abrasives Used for in Granite Polishing?

Headline: Cutting-Edge Satellite Abrasive Revolutionizes Granite IndustryIntroduction:In the ever-evolving world of technology, {Company Name} once again takes the lead with the launch of their groundbreaking satellite abrasive specifically designed for granite cutting. The innovative product, built on years of research and development, aims to revolutionize the granite industry by providing a more efficient and cost-effective solution for cutting and shaping granite.With its cutting-edge technology and dedication to delivering premium quality, {Company Name} has become a benchmark in the abrasive industry. Their expertise and commitment to excellence have made them a trusted name in the manufacturing sector.The Diamond Satellite Abrasive:The Diamond Satellite Abrasive for granite is a result of meticulous engineering, combining high-quality diamonds and advanced machinery. This unique blend ensures optimal cutting performance and outstanding tool life, saving time and resources for granite fabricators worldwide.Utilizing satellite technology, the abrasive tool is fitted with an array of diamond particles, uniformly distributed across its surface. This innovative method guarantees consistent cutting power and minimizes the risk of uneven cuts or surface imperfections. The interactive design of the abrasive tool ensures it adapts to the granite material, resulting in a superior finish.The Benefits:1. Enhanced Efficiency: The satellite abrasive's exceptional cutting capability streamlines the granite cutting process, significantly reducing production time. Fabricators no longer need to spend excessive hours on intricate shapes or complex designs, increasing productivity and profitability.2. Cost-Effectiveness: Through its efficient cutting action, the satellite abrasive minimizes wasted materials and lowers overall production costs. Granite fabricators can now optimize their resources, leading to higher profit margins.3. Superior Finish: The advanced technology embedded within the abrasive allows for a smoother and more refined finish on granite surfaces. Whether it is a countertop, flooring, or a custom-designed piece, the satellite abrasive offers an unmatched level of precision and finesse.4. Durability: {Company Name}'s commitment to quality ensures the satellite abrasive delivers outstanding durability, showcasing minimal wear and tear even after prolonged use. This longevity significantly reduces the need for frequent replacements, translating to cost savings for fabricators.Company Overview:{Company Name} has been at the forefront of the abrasives industry for over two decades. Founded on the principles of cutting-edge technology and a customer-centric approach, {Company Name} has earned a sterling reputation as a reliable and trusted abrasive manufacturer.Their state-of-the-art manufacturing facility is home to a team of highly skilled technicians and engineers, who strive for perfection in every product they create. Quality control measures are deeply ingrained throughout the production process, ensuring that each satellite abrasive that leaves the factory meets the highest industry standards.Furthermore, {Company Name} places considerable emphasis on sustainability and producing eco-friendly products. By minimizing waste and adopting environmentally friendly practices, they ensure that their products not only benefit their customers' businesses but also contribute positively to the environment.Conclusion:In an industry constantly searching for innovative solutions, {Company Name} has once again demonstrated their prowess by introducing the Diamond Satellite Abrasive for granite cutting. With its numerous advantages, including enhanced efficiency, cost-effectiveness, superior finish, and exceptional durability, this revolutionary product is set to transform the granite industry.As the company continues to push the boundaries of technology, fabricators worldwide can look forward to a future where granite cutting becomes more efficient, economical, and environmentally sustainable.

Uncovering the Marvels of Diamond Planetary Wheels: A Revolutionary Breakthrough in Engineering

Title: Breakthrough in Planetary Wheel Technology Revolutionizes Diamond IndustryIntroduction:In a significant development that promises to revolutionize the diamond industry, a groundbreaking technology known as the Planetary Wheel has emerged as a game-changer. Developed by an innovative company specializing in diamond cutting solutions, this new technology is set to enhance the efficiency, precision, and overall quality of diamond processing. With its potential to reshape the diamond industry landscape, this article delves into the intricacies of the Planetary Wheel and its implications for the diamond sector.Body:1. Evolution of Diamond Processing:Diamond processing has come a long way since its inception, with technology playing a vital role in enhancing the processes. With advancements in automation, precision cutting tools, and improved diamond analysis techniques, the industry has witnessed remarkable growth. However, the introduction of the Planetary Wheel technology marks a new chapter in this evolutionary journey.2. Understanding the Planetary Wheel:Developed by the company [], the Planetary Wheel is a pioneering technology capable of achieving unparalleled levels of precision and efficiency in diamond processing. This cutting-edge system leverages a unique combination of planetary gearing, which imparts a heightened level of control and stability to the entire process. By employing a planetary gear mechanism, the wheel ensures uniform distribution of loads, resulting in a higher quality cut and reduced rough diamond wastage.3. Advantages and Features of the Planetary Wheel:The Planetary Wheel offers a multitude of advantages that are poised to redefine diamond processing methodologies. Some of the key advantages include:A. Unmatched Precision: The innovative design of the Planetary Wheel ensures precise control over the cutting process, resulting in enhanced accuracy and finer cuts.B. Improved Stability: By evenly distributing loads, the Planetary Wheel minimizes vibrations, reducing the risk of damage to both the tool and the diamond. This increased stability ensures a longer lifespan for diamond cutting equipment.C. Enhanced Efficiency: The Planetary Wheel enables faster cutting rates, allowing for higher production output and reduced production costs.D. Diamond Preservation: With reduced wastage, the Planetary Wheel significantly improves the yield of polished diamonds from rough stones, maximizing the value of precious resources.4. Applications and Industry Impact:The impact of the Planetary Wheel technology spans across all segments of the diamond industry. From large cutting and polishing facilities to small-scale artisanal workshops, the enhanced precision, stability, and efficiency make it an attractive solution for all diamond processing operations. The technology allows manufacturers to increase production capacity and improve the quality of polished diamonds, catering to growing consumer demand for exceptional craftsmanship.5. Collaborative Efforts with Diamond Industry Stakeholders:The creators of the Planetary Wheel have actively engaged with industry stakeholders to ensure optimal integration of this technology. Collaborative efforts with diamond manufacturers, research institutions, and industry associations have enabled the development of specialized tools and processes that align with the requirements and patterns of the diamond industry. This collaborative approach has facilitated the adoption of the Planetary Wheel technology on a large scale, fostering innovation across the industry ecosystem.6. Future Prospects and Conclusion:The introduction of the Planetary Wheel technology has not only exemplified a major milestone in diamond processing but also underlined the industry's pursuit of continuous innovation. As the diamond market continues to evolve, this revolutionary technology will undoubtedly act as a catalyst for change. With its unparalleled precision, stability, and efficiency, the Planetary Wheel technology promises to elevate the standards of the diamond industry, ensuring a brighter future for manufacturers, retailers, and consumers alike.In conclusion, the Planetary Wheel technology has emerged as a groundbreaking force in the diamond industry, enabling unprecedented levels of precision, efficiency, and quality. As the industry embraces this cutting-edge technology, it is set to witness a transformative shift in diamond processing methodologies, maximizing resource utilization and meeting the demands of an ever-evolving market.

Expert Tips for Achieving a Flawless Polishing Plate

Polishing Plate, the Leading Name in Surface Refinement, Offers Unmatched Quality and PrecisionCompany XYZ Revolutionizes the Polishing Industry With Groundbreaking Techniques and State-of-the-Art Technology[date], [location] - Polishing Plate, a renowned player in the surface refinement industry, has emerged as the go-to destination for businesses seeking unparalleled quality and precision in their polishing needs. With a reputation for excellence, the company XYZ has redefined the art of polishing using groundbreaking techniques and cutting-edge technology, setting new industry standards.Polishing Plate takes pride in its commitment to delivering exceptional results to its ever-growing list of satisfied clients. With a meticulous attention to detail and a relentless pursuit of perfection, the company has firmly established itself as a leader in the field. Their expertise ranges from aerospace components, automotive parts, and medical devices to luxury goods, providing a diverse range of industries with top-notch polishing services."Our mission is to elevate the appearance and functionality of our clients' products through our exceptional polishing services," said [Spokesperson Name], the spokesperson of Polishing Plate. "We understand the value of precision and aesthetics, and we strive to bring out the true potential of every surface we work on. Our commitment to excellence has enabled us to build lasting relationships with our clients, who trust us to deliver superior results every time."Polishing Plate has set itself apart from competitors by employing a team of highly skilled technicians who possess immense knowledge and experience in the art of polishing. These experts understand the intricacies of various materials and surfaces, allowing them to tailor their techniques to achieve the desired outcome. Combining traditional craftsmanship with state-of-the-art technology, the team at Polishing Plate consistently delivers remarkable finishes that exceed client expectations.Furthermore, Polishing Plate has heavily invested in cutting-edge machinery and equipment, enabling them to maintain an unmatched level of precision and consistency throughout their processes. By leveraging these advanced tools, the company ensures every surface undergoes a thorough and uniform refinement, resulting in flawless finishes that enhance the overall quality and visual appeal of the product.One of the key factors contributing to Polishing Plate's success is its unwavering focus on customer satisfaction. The company believes in forging strong relationships with clients, understanding their unique needs, and providing personalized solutions that meet and exceed expectations. Polishing Plate's dedication to outstanding customer service has earned them a loyal clientele that spans across various industries.To remain at the forefront of the industry, Polishing Plate continually explores innovative techniques and embraces emerging technologies. Adopting sustainable practices, the company strives to reduce its environmental impact while consistently delivering exceptional results. Polishing Plate prides itself on contributing to a greener future, ensuring the longevity and sustainability of their business operations.In addition, Polishing Plate offers competitive pricing and flexible solutions, making their services accessible to businesses of all sizes. Whether it's a one-time polishing requirement or a long-term partnership, the company adapts to the specific needs and budgets of their clients without compromising on quality.As Polishing Plate continues to expand its operations and solidify its position as an industry leader, the company remains dedicated to delivering flawless and aesthetically pleasing surfaces that enhance the value and functionality of its clients' products. With their unwavering commitment to excellence, Polishing Plate is poised to redefine the boundaries of surface refinement, providing a platform for innovation and inspiration in the industry.About Polishing Plate:Polishing Plate, a leading surface refinement company, offers unmatched polishing services to various industries. With a focus on delivering exceptional results, the company combines traditional craftsmanship with cutting-edge technology to provide flawless finishes that enhance the quality and visual appeal of products. Polishing Plate's commitment to customer satisfaction, environmental sustainability, and continuous innovation sets them apart in the industry.

Efficient and Precise 250mm Chamfering Wheel for Resin Edges

Recently, a new 250mm Resin Edge Chamfering Wheel has caught the attention of many professionals in the industry. This product is specially designed for chamfering and deburring edges on a variety of materials, including metals, plastics, and ceramics. The innovative design and material used in the production of the chamfering wheel have made it one of the most effective solutions for edge grinding and finishing.The chamfering wheel is made of high-quality resin, which ensures that it is durable and can withstand harsh working conditions. The resin material is also known for its excellent heat resistance, which makes it a good choice for grinding and finishing tasks that generate high temperatures. The 250mm size of the chamfering wheel ensures that it can effectively cover the entire surface area of the material being worked on, making it easy to achieve a smooth and perfect finish.The design of the chamfering wheel is also one of the aspects that make it stand out from other products in the market. The wheel has a unique shape that allows it to reach corners and tight spaces with ease. This feature makes it perfect for working on complicated shapes and intricate designs. The chamfering wheel can also be used with different types of machines, including handheld grinders and bench grinders, making it versatile and convenient to use.One of the notable benefits of using the chamfering wheel is its ability to reduce the time and effort required for edge grinding and finishing. The wheel's high grinding efficiency ensures that the user can complete the task in less time, which improves productivity and reduces labor costs. The chamfering wheel also makes it easy to achieve a consistent and uniform finish, which enhances the overall appearance of the material.The 250mm Resin Edge Chamfering Wheel is manufactured by a renowned company that specializes in developing and producing abrasive tools for various applications. The company has a team of experienced engineers and technicians who ensure that all their products meet the required quality standards. They use advanced technology and machinery to produce high-quality abrasive tools that are effective and efficient.The company's commitment to quality and reliability has enabled them to establish a solid reputation in the industry. Their products are known for their durability and performance, which has earned them the trust and loyalty of many customers. The 250mm Resin Edge Chamfering Wheel is the latest addition to their line of abrasive tools, and it is already receiving positive reviews from users.In conclusion, the unveiling of the 250mm Resin Edge Chamfering Wheel is a significant development in the abrasive tools industry. This product's innovative design and material used in its production have made it a reliable and effective solution for edge grinding and finishing tasks. The chamfering wheel's efficiency, versatility, and ease of use make it an ideal tool for professionals in the metalworking, plastic, and ceramic industries. With this product, users can achieve a perfect and uniform finish in less time, which enhances productivity and reduces labor costs. The company's commitment to quality and reliability ensures that users of the chamfering wheel can enjoy long-term benefits from their investment.

New High-Quality Metal Bond Fickert for Improved Performance

Diamond Metal Bond Fickert: The Revolutionary Stone Grinding and Polishing SolutionGrinding and polishing natural stones has always been a time-consuming job that requires a high level of precision and often expensive machinery. However, with the advent of the Diamond Metal Bond Fickert, the process of stone grinding and polishing has been simplified and become incredibly efficient. This revolutionary solution has made grinding and polishing of natural stones an exciting and accessible process for everyone in the industry.The Diamond Metal Bond Fickert is a highly effective tool that can be used for grinding and polishing natural stones such as granite and marble. The product is made up of a metal base with diamond particles embedded on it, and can be used with any automated or manual polishing machine.The Diamond Metal Bond Fickert is highly efficient, allowing the user to grind and polish large areas of stone without requiring frequent tool changes. Additionally, the Fickert is designed to maintain a constant pressure throughout the entire grinding and polishing process, which ensures a consistent finish and improved performance.Combined with the right polishing pad, the Diamond Metal Bond Fickert can provide a superb polishing finish, reduce the amount of dust generated during the grinding process and make the entire process more efficient. Moreover, a diamond metal bond fickert last longer, reduces hand fatigue, and significantly reduces the overall cost of the polishing process.The Diamond Metal Bond Fickert has been extensively tested and proven in various polishing and grinding processes. In comparison to other stone grinding and polishing solutions, the Fickert is much superior, and eradicates the need for frequent tool changes, which is a time-consuming process. It is also worth noting that the Fickert wears minimally during grinding and polishing, which reduces downtime and repair costs.If you are in the stone grinding and polishing industry, the Diamond Metal Bond Fickert should be part of your arsenal. It is the perfect solution for achieving a high-quality finish on natural stones without sacrificing quality for speed, and is designed for durability and longevity.The company behind this cutting-edge technology manufactures a range of Fickerts and other stone grinding and polishing products that can help unlock the full potential of your machinery. Moreover, the company is highly invested in ensuring customer satisfaction and stands behind its products with warranties and customer support.Based on customer feedback, it is evident that the Diamond Metal Bond Fickert is one of the most popular and effective polishing tools on the market. The product is widely used in various industries, including construction, landscaping, and home decoration, and offers significant benefits to the user in terms of efficiency and overall output.In conclusion, the Diamond Metal Bond Fickert has revolutionized the stone grinding and polishing industry offering a cost-effective, efficient, and durable solution compared to traditional abrasives. It is a must-have tool for anyone in the industry, whether you are working in a large facility or a small shop. With this innovation, you are guaranteed a perfect finish on natural stones, minimized downtime, and reduced overall costs. Contact the company today for more information on how to add this innovative product to your polishing arsenal.

Discover the Art of Antique Brushes: Unraveling Timeless Beauty

In an era where technology has dominated nearly every aspect of our lives, there is an increasing appreciation for the simple, beautiful things that make life worth living. Moreover, a growing number of companies have recognized this trend and are striving to produce high-quality, handmade products that are both functional and aesthetically pleasing. Among these companies is a leading manufacturer of antique brushes, which has gained a reputation for crafting exquisite products that are loved by consumers around the world.{Company Name} is a highly regarded manufacturer of handcrafted antique brushes, a company which is dedicated to preserving the art of traditional brush making. The brushes produced by the company are handmade using the finest materials, including natural bristles and sustainable timber that is sourced from ethically managed forests. Each brush that they create is a reflection of the company's commitment to quality and attention to detail, which has earned them a loyal customer base and numerous accolades within the industry.In speaking with representatives of the company, it is clear that their passion for the craft of brush making is what drives them to produce the highest quality products. According to {Name}, the company's CEO, "the art of brush making is a time-honored tradition that we are proud to carry forward. Our brushes are made with the utmost care and attention to detail, which is why they have become so popular with customers around the world."The company's antique brushes are not just beautiful to look at, but are also built to last. They are made with such precision and durability that it is not uncommon for them to last for generations, and many customers purchase them with the intention of passing them down to future generations. The attention to detail that goes into the brush making process is evident in the care and precision that goes into each brush's design, ensuring that every brush produced by the company is a work of art.In addition to making high-quality antique brushes, {Company Name} is also dedicated to environmental sustainability. They source their materials from carefully managed forests, using only natural bristles and other materials that are environmentally friendly. Furthermore, they strive to reduce waste by using all of the materials that they source and minimizing any negative impact on the environment.The company's philosophy of creating beautiful, high-quality products that last for generations is a refreshing change from the fast-paced, disposable culture that has come to dominate modern society. Their commitment to traditional craftsmanship is a reminder that there is still a place for handmade products in today's world, and that beauty and functionality can be achieved without sacrificing quality or sustainability.In conclusion, {Company Name} is a company that is dedicated to preserving the art of traditional brush making while embracing modern innovations in manufacturing technology. They are committed to producing handmade, high-quality products that are both beautiful and sustainable, and they have earned a reputation as a leading manufacturer of antique brushes. Their dedication to quality and attention to detail is evident in every brush they produce, and their commitment to environmental sustainability is a reminder that we can still enjoy the simple things in life without sacrificing the planet we call home.

A Comprehensive Guide to Using Resin Bond Diamond Polishing Pads

Introducing the Revolutionary Resin Bond Diamond Polishing Pad: A Game-Changer in Surface PolishingIn the ever-evolving world of construction and home improvement, advancements in technology and materials continue to shape the industry. One such groundbreaking product that has gained immense popularity is the Resin Bond Diamond Polishing Pad. This innovative tool has revolutionized surface polishing, delivering unparalleled results and transforming the way professionals approach their projects.The Resin Bond Diamond Polishing Pad, developed by a leading manufacturer in the field, is crafted with cutting-edge technology and precision engineering. The unique resin bond system serves as a bonding agent, effectively attaching the diamond abrasive grains to the polishing pad base. This results in enhanced effectiveness and durability, making it an exceptional choice for a wide range of polishing applications.With its superior design, the Resin Bond Diamond Polishing Pad offers several advantages that set it apart from traditional polishing pads. Firstly, it excels in material removal, making quick work of surface imperfections, scratches, and blemishes. This efficiency allows professionals to save time and effort while achieving an immaculate finish.Additionally, the Resin Bond Diamond Polishing Pad provides exceptional polishing performance. Its diamond abrasive grains ensure a high degree of precision and consistency, delivering a flawless shine on various surfaces, including marble, granite, concrete, and terrazzo. Whether it's a large-scale project or a delicate countertop, this pad guarantees outstanding results.Furthermore, this advanced tool boasts an extended lifespan, vastly surpassing traditional abrasive pads on the market. Its durability is attributed to the unique resin bond system, which effectively prevents premature wear and tear, maintaining the pad's effectiveness and longevity even after multiple uses. This long-lasting nature translates into substantial cost savings for professionals, who can rely on the pad to withstand rigorous polishing projects.The Resin Bond Diamond Polishing Pad also showcases remarkable heat resistance during prolonged use. This feature is crucial in preventing heat damage to the surface being polished. With this pad, professionals can confidently work on large surfaces without the worry of overheating, ensuring optimal results without compromise.Moreover, the Resin Bond Diamond Polishing Pad is designed with ease of use in mind. Its flexibility allows it to adapt to various shapes and contours, enabling professionals to achieve consistent and uniform polishing results even in hard-to-reach areas. This versatility proves invaluable in demanding projects, ensuring a smooth and efficient polishing process.With safety being a top priority, the Resin Bond Diamond Polishing Pad incorporates an innovative design that minimizes the possibility of accidents or injuries while in use. Its ergonomic construction, coupled with quality control standards, guarantees a secure grip and reduces the risk of slippage during operation. This attention to safety underscores the manufacturer's commitment to providing not only exceptional performance but also peace of mind for professionals.In conclusion, the Resin Bond Diamond Polishing Pad is a groundbreaking product that has redefined the surface polishing industry. Its outstanding material removal capabilities, exceptional polishing performance, extended lifespan, heat resistance, ease of use, and emphasis on safety make it a game-changer in the field. Professionals can rely on this innovative tool to achieve immaculate finishes, save time and cost, and enhance their overall productivity. With its introduction, surface polishing will never be the same again.

High-Quality 180mm Metal Bond Diamond Grinding Disc: Enhanced Durability and Precision

Title: Cutting-Edge Metal Bond Diamond Grinding Disc Revolutionizes Precision GrindingSubtitle: Industry-Leading Company Unveils Game-Changing Solution for Surface GrindingDate: [Current Date][City], [State] - In a breakthrough development, leading industry innovator [Company Name] has launched its latest offering - the 180mm Metal Bond Diamond Grinding Disc [removed brand name]. This cutting-edge product is set to redefine the precision grinding industry, presenting new possibilities for professionals seeking exceptional results.As industries demand increasingly higher standards for precision and surface quality, [Company Name] has risen to the challenge and introduced a product that truly goes above and beyond. The 180mm Metal Bond Diamond Grinding Disc utilizes state-of-the-art technology to deliver outstanding performance, efficiency, and durability.The foundation of this ground-breaking innovation is the use of metal bond diamond abrasives. Renowned for their exceptional toughness and wear resistance, these abrasives provide an enhanced grinding experience. By leveraging their vast industry expertise and cutting-edge research, [Company Name] has successfully integrated metal bond diamond abrasives into their latest disc, ensuring an unparalleled level of precision.One of the standout features of the 180mm Metal Bond Diamond Grinding Disc is its ability to tackle a wide range of materials with ease. Whether it is granite, marble, concrete, or any other hard material, this disc consistently delivers exceptional results. With its superior cutting efficiency and enhanced durability, professionals can save valuable time and money.The product also boasts an optimized design that allows for smooth and consistent grinding throughout its usage. The careful engineering behind the disc enables users to achieve intricate and accurate profiling, making it a versatile tool for a wide range of applications. The disc's long lifespan further enhances its value, minimizing the need for frequent replacements and reducing operational costs.[Company Name], a renowned industry leader, has long been committed to pushing the boundaries of innovation. Catering to diverse customer needs, they specialize in the development and production of high-quality grinding tools. Their relentless pursuit of excellence has solidified their position as a trusted provider of cutting-edge solutions.Backed by years of experience, [Company Name] has embraced the latest advancements in materials and technology. Through continuous research and development, they have ensured that their products consistently meet the ever-evolving demands of the market. With an unwavering dedication to customer satisfaction, they have become an invaluable partner for professionals across various industries.The launch of the 180mm Metal Bond Diamond Grinding Disc is a reflection of [Company Name]'s commitment to customer-centric innovation. By integrating industry-leading features into their products, they empower professionals to stay ahead in an increasingly competitive market.At [Company Name], customer satisfaction is paramount. To ensure the highest level of quality control, each disc undergoes rigorous testing and inspection before reaching the hands of the users. [Company Name] stands by their products with comprehensive customer support, assisting professionals at every step of their grinding processes.The 180mm Metal Bond Diamond Grinding Disc is set to make a resounding impact in the precision grinding industry, empowering professionals to achieve superior results with efficiency and ease. Backed by cutting-edge technology and the reputation of [Company Name], this product is poised to become an indispensable tool for surface grinding applications across various sectors.In conclusion, the 180mm Metal Bond Diamond Grinding Disc, launched by [Company Name], offers an innovative solution for precision grinding. With its incorporation of metal bond diamond abrasives, this disc stands on the forefront of the industry, guaranteeing exceptional performance, durability, and versatility. [Company Name]'s commitment to innovation and customer satisfaction solidifies their position as a trusted provider of high-quality grinding tools. Professionals can embrace this game-changing product and experience unparalleled precision and efficiency in their grinding endeavors.