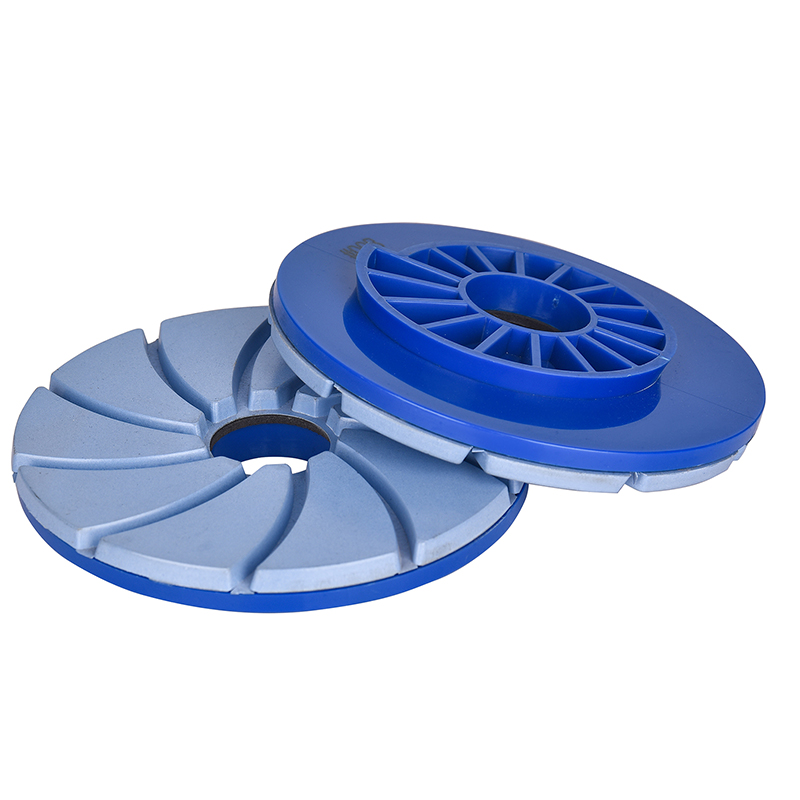

High-Quality Resin Bond Diamond Grinding Discs for Efficient Cutting and Polishing

By:Admin

The Whole Resin Bond Diamond Grinding Disc is a versatile and high-performance tool that has been designed to meet the needs of professionals in the grinding and polishing industry. With a focus on precision and efficiency, this diamond grinding disc offers superior performance and longevity, making it an ideal choice for a wide range of grinding applications.

One of the key features of the Whole Resin Bond Diamond Grinding Disc is its advanced resin bond technology, which provides exceptional bonding strength and wear resistance. This allows the disc to maintain its shape and cutting ability even under heavy use, ensuring consistent and reliable performance over time. The high-quality diamond abrasive material used in the disc further enhances its cutting power and durability, making it suitable for grinding various materials including concrete, stone, and masonry.

The company behind this innovative product is committed to providing customers with high-quality diamond tools that deliver exceptional value and performance. With a team of skilled engineers and technicians, the company invests heavily in research and development to constantly improve its product offerings and stay ahead of the competition. This dedication to innovation and excellence has earned the company a strong reputation in the industry, making it a trusted partner for professionals and businesses looking for reliable diamond tools and equipment.

In addition to its focus on quality, the company also places a strong emphasis on customer satisfaction and support. With a customer-centric approach, the company strives to provide personalized service and support to meet the specific needs of its clients. This includes offering expert advice and guidance on selecting the right tools for specific applications, as well as providing timely technical support and after-sales service to ensure the optimal performance and longevity of its products.

The company's commitment to quality and customer satisfaction has earned it a loyal customer base and a strong presence in the market. Professionals and businesses trust the company's products to deliver exceptional performance and value, making it a preferred choice for diamond tools and equipment. With a wide range of diamond tools and equipment available, including grinding discs, cutting blades, and polishing pads, the company continues to be a leading supplier for various industrial applications.

The Whole Resin Bond Diamond Grinding Disc is a testament to the company's dedication to excellence and innovation. With its advanced technology and superior performance, this product has set a new standard for quality and reliability in the industry. Whether for grinding concrete, stone, or masonry, professionals can rely on this diamond grinding disc to deliver exceptional results and maximize productivity.

As the company continues to push the boundaries of diamond tool technology, it remains a trusted partner for professionals and businesses looking for high-quality, reliable tools and equipment. With its strong commitment to innovation, quality, and customer satisfaction, the company is poised to maintain its leadership position in the industry and continue delivering cutting-edge solutions for various industrial applications.

Company News & Blog

Discover the Benefits of Using Polishing Bricks for Resin Frankfurt

Resin Frankfurt Polishing Brick Revolutionizes the Stone Polishing Industry[City, Date] – Industry-leading manufacturing company, [Company Name], has introduced an innovative solution for the stone polishing industry, the Resin Frankfurt Polishing Brick. This revolutionary product promises to streamline the stone polishing process, delivering exceptional results with minimal effort. With its cutting-edge technology and commitment to quality, [Company Name] continues to cement its position as a key player in the manufacturing sector.The Resin Frankfurt Polishing Brick is designed to remove imperfections, scratches, and blemishes from various surfaces, including marble, granite, and engineered stone. The brick's resin bond ensures high efficiency, durability, and resistance to wear, providing professionals and DIY enthusiasts with a reliable tool for their stone polishing needs.[Company Name] has always prioritized research and development to offer only the best solutions in the market. The Resin Frankfurt Polishing Brick is a testament to their dedication to innovation and the advancement of the industry. Constructed with premium-quality materials and utilizing state-of-the-art manufacturing processes, this polishing brick sets a new standard for excellence in the stone polishing sector.One of the key features of the Resin Frankfurt Polishing Brick is its versatility. It can be used for both wet and dry polishing applications, making it suitable for a wide range of projects. The brick's exceptional polishing capabilities ensure a smooth and flawless finish, enhancing the natural beauty of the stones. With its ability to produce consistent, high-quality results, this polishing brick is quickly becoming an essential tool for professionals in the field.The Resin Frankfurt Polishing Brick is also designed with ease of use in mind. Its ergonomic shape and lightweight construction allow for comfortable handling, reducing fatigue during long polishing sessions. The brick's adaptability to various polishing machines further enhances its user-friendliness, ensuring that professionals can easily integrate this product into their existing workflow.In addition to its exceptional performance, the Resin Frankfurt Polishing Brick is also environmentally friendly. Manufactured using sustainable practices, [Company Name] ensures that their products have minimal impact on the environment. This commitment to sustainability aligns with their overall ethos of responsible manufacturing.As a pioneer in the industry, [Company Name] has established a strong reputation for delivering unmatched quality and customer satisfaction. The introduction of the Resin Frankfurt Polishing Brick solidifies their commitment to excellence, further cementing their position as an industry leader. With their comprehensive product range and unparalleled expertise, [Company Name] continues to provide cutting-edge solutions to their customers around the globe.Industry professionals who have had the opportunity to test the Resin Frankfurt Polishing Brick have praised its effectiveness and efficiency. Some have described it as a game-changer, drastically reducing their polishing time while enhancing the overall finish. With positive feedback pouring in, it is evident that [Company Name] has once again successfully met and exceeded the needs of its customers.Moving forward, [Company Name] aims to maintain its position at the forefront of the stone polishing industry. Through continuous innovation and an unwavering commitment to quality, they strive to develop products that meet the evolving demands of their customers. With the Resin Frankfurt Polishing Brick already making waves in the market, it is clear that [Company Name] is poised for continued success.About [Company Name]:[Company Name] is a leading manufacturing company specializing in the production of high-quality stone processing tools. With a commitment to innovation and customer satisfaction, they have earned a reputation for delivering exceptional products that revolutionize the industry. With a diverse product range and a global customer base, [Company Name] continues to push boundaries and set new standards for excellence.

Top Diamond Wet Polishing Pad for Efficient Polishing

Diamond Wet Polishing Pad Takes the Market by StormDiamond Wet Polishing Pad, a revolutionary product from a leading company in the diamond tool manufacturing industry, has taken the market by storm. The company, which has been in the business for over two decades, has a reputation for delivering top-of-the-line products that set the industry standards. The Diamond Wet Polishing Pad is no exception.The Diamond Wet Polishing Pad is designed to deliver a high-quality finish on various materials, including granite, marble, and other natural stones. The product comes in multiple grit levels, including 50, 100, 200, 400, 800, 1500, and 3000, allowing users to achieve the desired finish. The product is also available in various sizes, including 3, 4, and 5 inches, which makes it ideal for use on different machines.What sets the Diamond Wet Polishing Pad apart from other polishing pads in the market is its durability and effectiveness. The pad is made using premium-grade diamond particles, which are embedded in a resin matrix that provides outstanding durability and performance. The pad also has a high diamond concentration, which ensures fast and efficient polishing, reducing the time and effort needed to achieve the desired results.The Diamond Wet Polishing Pad is also designed with a unique water channeling system that ensures efficient water flow to the surface, further enhancing the polishing process. The system also helps in reducing heat buildup during polishing, which can be detrimental to the pad's lifespan.The Diamond Wet Polishing Pad is not only an excellent tool for professional fabricators and contractors, but it is also ideal for DIY enthusiasts. The product is easy to use, even for first-time users, and comes with clear instructions on how to use it. Additionally, it is a cost-effective solution that allows users to achieve professional-grade finishes without breaking their budgets.Customers who have used the Diamond Wet Polishing Pad have reported excellent results and praised the product's durability and efficiency. They have also noted that the product is easy to use and comes at an affordable price point compared to other high-end polishing pads in the market.In conclusion, the Diamond Wet Polishing Pad is a game-changer in the diamond tool manufacturing industry. Its durability, efficiency, and cost-effectiveness make it an ideal tool for fabricators, contractors, and DIY enthusiasts alike. The product has received excellent customer reviews, and it is set to become the go-to polishing pad for professionals and hobbyists alike. The company behind the product is confident that it will continue to set the industry standard and cement its position as a market leader in the diamond tool manufacturing industry.

Discover High-Quality Abrasive Tools for Ceramic Surfaces

Title: Innovative Abrasive Tools for Ceramic Applications Revolutionize Precision Machining IndustryIntroduction:[Company Name], a leading player in the manufacturing of advanced industrial tools, continues to push the boundaries of technology with its latest development - an exclusive line of high-performance abrasive tools for ceramic applications. This breakthrough innovation is poised to revolutionize the precision machining industry by improving the efficiency, accuracy, and durability of ceramic material processing. With years of experience in the field, [Company Name] has a strong reputation for delivering cutting-edge solutions to meet the evolving needs of a diverse clientele. This news article delves into the remarkable features of these abrasive tools and sheds light on how they are transforming the landscape of ceramic machining.1. Unparalleled Precision and Efficiency:The new line of abrasive tools for ceramic offered by [Company Name] boasts exceptional precision and efficiency, enabling manufacturers to achieve superior surface finishes and dimensional accuracy. Developed using advanced materials, these tools minimize material wastage and reduce the need for additional finishing processes. By streamlining operations, manufacturers can significantly enhance productivity, reduce lead times, and optimize resource utilization. The tools' high-performance grit structure ensures consistent removal rates, ensuring efficient cutting and grinding throughout the ceramic machining process.2. Enhanced Durability and Longevity:[Company Name]'s abrasive tools are designed to withstand the demanding and often harsh conditions encountered during ceramic machining. Through extensive research and development, these tools exhibit outstanding wear resistance, reducing the frequency of tool replacement and minimizing downtime. The company's deep understanding of the unique properties of ceramic materials has enabled them to create abrasives that remain sharp during extended periods of use. The exceptional durability of these tools ultimately leads to reduced operational costs and increased overall productivity.3. Versatile Applications:The versatility of the abrasive tools manufactured by [Company Name] allows them to cater to a wide range of ceramic machining applications. From cutting and shaping precise components to grinding intricate shapes, these tools consistently deliver unmatched performance across varied machining operations. Whether it is working with oxide ceramics, non-oxide ceramics, or composites, manufacturers can rely on [Company Name]'s abrasive tools to achieve impeccable results across diverse sectors such as aerospace, automotive, electronics, and medical industries.4. Technological Advancements:It is [Company Name]'s relentless pursuit of technological advancements that has propelled its abrasive tools to new heights. Through state-of-the-art manufacturing processes and continuous research, the company has refined its tools to enhance their cutting efficiency and precision. Computer-aided modeling and simulation techniques have enabled the company to optimize geometries and ensure uniform distribution of abrasive particles, resulting in improved surface finishes and reduced machining times. Moreover, the implementation of innovative bonding agents enhances the tools' structural integrity, allowing them to withstand high-speed operations without compromising precision or longevity.5. Commitment to Sustainability:[Company Name] maintains a strong dedication to environmental responsibility. In line with this commitment, the company has developed eco-friendly abrasive tools for ceramic machining. These tools are free from harmful substances and designed to minimize waste during the manufacturing process. By incorporating sustainable practices and materials, [Company Name] actively contributes to the reduction of environmental impact within the precision machining industry.Conclusion:[Company Name]'s groundbreaking abrasive tools for ceramic machining have delighted manufacturers worldwide with their unrivaled precision, efficiency, durability, and versatility. As the demand for ceramic components in various industries continues to grow, these innovative tools are set to play a pivotal role in revolutionizing precision machining processes. Through its relentless pursuit of excellence and commitment to technological advancements, [Company Name] solidifies its position as a leading provider of cutting-edge solutions that drive the industry forward.

Discover the Efficiency of 6-Inch Wet 3-Step Polishing Pads for Diamond Polishing

Title: Advanced Polishing Technology Unveiled by Leaders in Diamond Tools ManufacturingIntroduction:In an exciting development, a renowned company in diamond tools manufacturing has launched a groundbreaking product in the field of polishing pads. The all-new 6 Inch Diamond Wet 3 Steps Polishing Pad has set new standards of excellence, providing professionals with an advanced tool to achieve remarkable results. With its unique features and superior quality, this latest offering is set to revolutionize the industry. Let's dive into the details of this remarkable product that is already making waves in the market.Revolutionizing Polishing Techniques:The new 6 Inch Diamond Wet 3 Steps Polishing Pad comes as a game-changer for professionals who seek the highest level of precision and quality in their polishing work. The latest technology utilized in its manufacturing imbues it with exceptional features, making it an essential tool in the arsenal of every polishing expert.Unparalleled Performance:One of the key advantages of this innovative polishing pad is its ability to achieve unparalleled performance through three simple steps. The specially designed grit sequences offer efficient polishing for various surfaces, eliminating the need for multiple pads. This not only saves time but also enhances productivity, making it a cost-effective choice for professionals.Long-lasting Durability:The durability of the 6 Inch Diamond Wet 3 Steps Polishing Pad is second to none. Crafted from high-quality materials, this pad is built to withstand rigorous usage, providing an extended lifespan. Its robust construction allows it to maintain its effectiveness even when subjected to demanding polishing conditions, ensuring consistent results over time.Exceptional Polishing Results:The advanced technology employed in the manufacturing process translates into outstanding polishing results. The 6 Inch Diamond Wet 3 Steps Polishing Pad ensures a mirror-like finish with unparalleled clarity and depth, enhancing the overall aesthetic appeal of the surfaces it is used on. Whether it is granite, marble, or concrete, this pad proves to be a reliable companion in achieving flawless results.Versatility and Ease of Use:The versatility of the 6 Inch Diamond Wet 3 Steps Polishing Pad makes it suitable for a wide range of applications. From small residential projects to large-scale commercial ventures, this pad adapts to various surfaces with ease, providing consistent and remarkable outcomes. With user-friendly features, such as easy attachment and detachment, it offers convenience and hassle-free operation, even for beginners.Environmental Considerations:Recognizing the importance of sustainability, the manufacturing process of the 6 Inch Diamond Wet 3 Steps Polishing Pad has been designed to minimize its environmental impact. The company prioritizes utilizing eco-friendly materials and processes, making a significant contribution toward a greener and more sustainable future.Industry-Standard Compliance:In line with its commitment to excellence, the company ensures that the 6 Inch Diamond Wet 3 Steps Polishing Pad complies with all relevant industry standards and regulations. Stringent quality control measures are in place to guarantee that each pad meets the highest level of performance and safety, instilling confidence in professionals who rely on this essential tool.Conclusion:With the launch of the 6 Inch Diamond Wet 3 Steps Polishing Pad, the diamond tools manufacturing industry has witnessed a remarkable breakthrough. This cutting-edge product has revolutionized polishing techniques, providing professionals with an exceptional tool that ensures unparalleled performance, durability, and efficiency. With its versatility and eco-friendly manufacturing process, it has already made a significant impact in the market. Embracing this advanced polishing solution is a step toward elevating the standards of polishing work to new heights.

140mm Diamond Resin Fickert for Stone Grinding and Polishing

The 140mm Buff Fickert, a revolutionary new product in the field of stone processing, has been making waves in the industry since its launch. Manufactured by a leading company specializing in diamond tools, the Buff Fickert has quickly become a game changer in the stone polishing process.The company, with over 20 years of experience in the production of diamond tools and stone processing equipment, has earned a reputation for its high-quality products and innovative solutions. The introduction of the 140mm Buff Fickert is yet another testament to their dedication to delivering cutting-edge technology that meets the evolving needs of their customers.The Buff Fickert is a type of abrasive tool that is used for the fine grinding and polishing of various types of natural and engineered stones. Its unique design and composition make it highly effective in achieving a high-gloss finish, while also ensuring a long service life. This innovative product has quickly gained traction in the industry due to its superior performance and cost-effectiveness.One of the key features of the 140mm Buff Fickert is its versatility. It is compatible with a wide range of automatic polishing machines, making it suitable for use in various stone processing applications. Whether it is marble, granite, quartz, or other types of stones, the Buff Fickert delivers consistent and exceptional results, making it a valuable tool for stone processing professionals.Moreover, the Buff Fickert is designed to minimize heat generation during the polishing process, which helps to prevent damage to the surface of the stone. This not only ensures a superior finish but also extends the lifespan of the stone, making it an environmentally friendly choice for stone processing.The company's commitment to quality and innovation is evident in the extensive research and development that went into the creation of the Buff Fickert. By leveraging the latest advancements in abrasive technology, they have been able to deliver a product that sets a new standard for stone polishing, earning the trust and praise of professionals in the industry.In addition to its superior performance, the 140mm Buff Fickert also offers excellent value for money. Its long service life and high efficiency make it a cost-effective solution for stone processing businesses, helping them to improve their productivity and meet the demands of their customers.The success of the Buff Fickert can also be attributed to the company's commitment to customer satisfaction. Their dedication to providing prompt and reliable customer support has made them a trusted partner for stone processing professionals around the world. With a global distribution network and a strong focus on after-sales service, they ensure that their customers have access to the Buff Fickert and other products whenever and wherever they need them.As the demand for high-quality stone processing tools continues to grow, the 140mm Buff Fickert has emerged as a game-changing product that is reshaping the industry. Its exceptional performance, versatility, and cost-effectiveness have made it a sought-after choice for professionals who are looking to elevate their stone polishing capabilities.In conclusion, the introduction of the 140mm Buff Fickert marks a significant milestone in the field of stone processing. Backed by a company with a proven track record of delivering excellence, this innovative product is setting new standards for performance and efficiency, while also reaffirming the company's position as a leader in the industry. With the Buff Fickert, stone processing professionals can expect nothing less than exceptional results, ensuring that their projects stand out for their quality and finish.

Enhancing Productivity with the Revolutionary Compound Abrasive in Frankfurt

Frankfurt Compound Abrasive Has Revolutionized the Polishing IndustryFrankfurt Compound Abrasive is an innovative product that has taken the polishing industry by storm. This groundbreaking compound has quickly become the go-to choice for professionals and DIY enthusiasts alike, thanks to its exceptional performance and ease of use.Developed by a renowned company in the field of abrasives, {Company Name}, this compound has been formulated to deliver superior results on various surfaces, including marble, granite, and concrete. Its unique composition consists of high-quality abrasive particles embedded in a resin matrix, ensuring optimal polishing performance with minimal effort.One of the key advantages of Frankfurt Compound Abrasive is its versatility. It can be used with different polishing machines, such as hand-held polishers or floor machines, making it suitable for a wide range of applications. Whether you need to polish small, intricate surfaces or large floor areas, this compound provides consistent and reliable results.Furthermore, Frankfurt Compound Abrasive is designed to be long-lasting, ensuring that you get the most out of each application. Its high-quality composition resists wear and tear, allowing for extended use without compromising on performance. This not only saves time and money but also ensures a consistent finish throughout the entire polishing process.In addition to its durability, Frankfurt Compound Abrasive is known for its exceptional polishing capabilities. The abrasive particles in the compound effectively remove scratches, stains, and blemishes on the surface, revealing a smooth and glossy finish. This remarkable polishing action is achieved without leaving any swirl marks or uneven spots, resulting in a flawless appearance.Another noteworthy feature of Frankfurt Compound Abrasive is its user-friendly nature. The compound is easy to apply and does not require specialized skills or training. Simply attach the appropriate polishing pad to your machine, apply a small amount of the compound, and start polishing. Its consistent texture and ease of spread ensure a uniform application, while its quick-drying formula allows for efficient use of time.Furthermore, Frankfurt Compound Abrasive is formulated to minimize dust and residue during the polishing process. This not only provides a cleaner working environment but also reduces the need for extensive cleanup afterward. The compound's low dust generation also contributes to a healthier working environment for operators, reducing respiratory risks commonly associated with abrasive materials.Beyond its impressive performance, Frankfurt Compound Abrasive is also environmentally friendly. The compound is free from harmful chemicals and toxins, ensuring a safe and sustainable polishing solution. Its water-based formula eliminates the need for harsh solvents and reduces potential harm to both users and the environment.With its numerous advantages, Frankfurt Compound Abrasive has revolutionized the polishing industry. Professionals now rely on this innovative product to achieve exceptional results efficiently, while DIY enthusiasts appreciate its ease of use and consistent performance. As the go-to choice for polishing various surfaces, this compound has set a new standard for quality and reliability in the industry.In conclusion, Frankfurt Compound Abrasive, developed by {Company Name}, has proven to be a game-changer in the polishing industry. This versatile, long-lasting, and high-performing compound offers remarkable polishing capabilities, ease of use, and eco-friendliness. With its revolutionary properties, Frankfurt Compound Abrasive has cemented its position as the preferred choice for polishing professionals and enthusiasts alike.

High-Quality 170mm Metal Diamond Fickert for Stone Grinding and Polishing

[Company Name], a leading manufacturer of high-quality diamond tools and equipment, has recently launched a new product in its lineup of diamond fickert tools: the 170mm Metal Diamond Fickert. This latest addition to [Company Name]'s range of diamond tools is designed to meet the evolving needs of the stone processing industry, offering increased efficiency and longevity for users.The 170mm Metal Diamond Fickert is meticulously crafted using high-quality materials and precision engineering, ensuring outstanding performance and durability. With a focus on providing reliable and consistent results, this diamond fickert is suitable for a wide range of stone processing applications, including grinding and polishing of granite, marble, and other natural stone surfaces.One of the key features of the 170mm Metal Diamond Fickert is its advanced metal bond technology, which is specifically engineered to deliver superior grinding and polishing capabilities. This innovative bond system allows for efficient stock removal while maintaining excellent surface finish, making it an ideal choice for stone processing professionals looking to achieve high-quality results in a timely manner.In addition to its advanced bond technology, the 170mm Metal Diamond Fickert also incorporates high-quality diamond segments that are carefully positioned for optimal performance. These diamond segments are designed to provide consistent and precise grinding and polishing action, enabling users to achieve smooth and uniform surfaces on a variety of stone materials.Furthermore, [Company Name] takes pride in its commitment to sustainability and environmental responsibility. As such, the 170mm Metal Diamond Fickert is engineered to minimize its environmental impact by reducing energy consumption and waste generation during the stone processing process. This environmentally conscious approach reflects [Company Name]'s dedication to promoting eco-friendly practices within the industry.With the introduction of the 170mm Metal Diamond Fickert, [Company Name] continues to solidify its position as a trusted provider of diamond tools and equipment for the stone processing industry. The company's extensive experience and expertise in manufacturing high-performance diamond tools have earned it a reputation for delivering reliable and innovative solutions that meet the evolving needs of its customers.[Company Name] is committed to supporting its customers with exceptional products and comprehensive technical support, ensuring that they can maximize the performance and longevity of their diamond tools. The company's team of skilled professionals is readily available to provide guidance and assistance to users, helping them make informed decisions about the best tools for their specific stone processing requirements.Those interested in learning more about the 170mm Metal Diamond Fickert or exploring [Company Name]'s complete range of diamond tools and equipment can visit the company's website or contact its customer service team for personalized assistance. With a strong focus on quality, performance, and customer satisfaction, [Company Name] remains a leading manufacturer of diamond tools that continue to set new benchmarks in the stone processing industry.

High-Quality Resin Bond Diamond Grinding Discs for Efficient Cutting and Polishing

Whole Resin Bond Diamond Grinding Disc, a product by a renowned company in the field of diamond tools and equipment, has been making strides in the market with its exceptional performance and reliability. The company, with a strong commitment to innovation and quality, has been a leading supplier of diamond tools for various industrial applications for many years.The Whole Resin Bond Diamond Grinding Disc is a versatile and high-performance tool that has been designed to meet the needs of professionals in the grinding and polishing industry. With a focus on precision and efficiency, this diamond grinding disc offers superior performance and longevity, making it an ideal choice for a wide range of grinding applications.One of the key features of the Whole Resin Bond Diamond Grinding Disc is its advanced resin bond technology, which provides exceptional bonding strength and wear resistance. This allows the disc to maintain its shape and cutting ability even under heavy use, ensuring consistent and reliable performance over time. The high-quality diamond abrasive material used in the disc further enhances its cutting power and durability, making it suitable for grinding various materials including concrete, stone, and masonry.The company behind this innovative product is committed to providing customers with high-quality diamond tools that deliver exceptional value and performance. With a team of skilled engineers and technicians, the company invests heavily in research and development to constantly improve its product offerings and stay ahead of the competition. This dedication to innovation and excellence has earned the company a strong reputation in the industry, making it a trusted partner for professionals and businesses looking for reliable diamond tools and equipment.In addition to its focus on quality, the company also places a strong emphasis on customer satisfaction and support. With a customer-centric approach, the company strives to provide personalized service and support to meet the specific needs of its clients. This includes offering expert advice and guidance on selecting the right tools for specific applications, as well as providing timely technical support and after-sales service to ensure the optimal performance and longevity of its products.The company's commitment to quality and customer satisfaction has earned it a loyal customer base and a strong presence in the market. Professionals and businesses trust the company's products to deliver exceptional performance and value, making it a preferred choice for diamond tools and equipment. With a wide range of diamond tools and equipment available, including grinding discs, cutting blades, and polishing pads, the company continues to be a leading supplier for various industrial applications.The Whole Resin Bond Diamond Grinding Disc is a testament to the company's dedication to excellence and innovation. With its advanced technology and superior performance, this product has set a new standard for quality and reliability in the industry. Whether for grinding concrete, stone, or masonry, professionals can rely on this diamond grinding disc to deliver exceptional results and maximize productivity.As the company continues to push the boundaries of diamond tool technology, it remains a trusted partner for professionals and businesses looking for high-quality, reliable tools and equipment. With its strong commitment to innovation, quality, and customer satisfaction, the company is poised to maintain its leadership position in the industry and continue delivering cutting-edge solutions for various industrial applications.

Durable and Long-Lasting Resin Discs: A New Advancement in Construction Materials

Resin Disc Launches Innovative Recycling Program to Reduce Plastic WasteIn recent years, the global issue of plastic waste has become a growing concern for individuals and organizations around the world. As a result, many companies have been seeking innovative solutions to reduce plastic usage and promote more sustainable practices. One such company, Resin Disc, has recently launched an innovative recycling program aimed at addressing this pressing environmental issue.Resin Disc, a leading provider of high-quality resin products, has recognized the urgency of tackling the growing problem of plastic waste. With this in mind, they have developed a revolutionary recycling program that is poised to make a significant impact on the environment. By utilizing state-of-the-art recycling technology, Resin Disc is paving the way for a more sustainable future by transforming used plastic materials into new, high-quality resin products.The company's commitment to environmental responsibility is evident in their dedication to reducing the environmental impact of plastic waste. Through their innovative recycling program, Resin Disc is not only minimizing the amount of plastic that ends up in landfills and oceans, but also contributing to the conservation of natural resources. By repurposing used plastic materials, the company is significantly reducing the demand for new raw materials, thereby lessening the environmental strain associated with the production of plastic products.Moreover, Resin Disc's recycling program offers a practical and convenient solution for businesses and individuals alike to responsibly dispose of their plastic waste. By partnering with Resin Disc, companies and consumers can ensure that their used plastic materials are being recycled in an environmentally-friendly manner, rather than contributing to the growing problem of plastic pollution. This initiative not only aligns with Resin Disc's commitment to sustainability, but also reflects their desire to inspire positive change within the community.In addition to their environmental stewardship, Resin Disc is also dedicated to providing their customers with the highest quality resin products on the market. With their state-of-the-art recycling technology, the company is able to transform used plastic materials into new resin products that rival the quality of virgin resin. This not only demonstrates Resin Disc's commitment to sustainability, but also underscores their unwavering dedication to delivering superior products that meet the highest industry standards.As an industry leader, Resin Disc's innovative approach to recycling has the potential to revolutionize the way that companies and consumers view plastic waste. By offering a viable solution to the plastic pollution crisis, the company is not only fostering a more sustainable future, but also setting a positive example for others within the industry to follow. Through their recycling program, Resin Disc is actively promoting a culture of environmental responsibility and encouraging others to join the fight against plastic waste.As the world continues to grapple with the environmental impact of plastic waste, companies like Resin Disc are leading the charge in developing practical and effective solutions to this complex issue. Through their commitment to environmental responsibility and their innovative approach to recycling, Resin Disc is demonstrating that it's possible for businesses to make a positive impact on the environment while still delivering high-quality products to their customers. With their groundbreaking recycling program, Resin Disc is proving that a sustainable future is within reach, and inspiring others to follow suit in the global effort to reduce plastic waste.

High-Quality Diamond Resin Bond Chamfering Wheel for Precision Grinding

[Company Introduction]Established in 1998, our company has been a leading manufacturer and supplier of cutting-edge abrasive tools for the metalworking and woodworking industries. With a strong focus on research and development, we have consistently delivered high-quality products that meet the evolving demands of our customers. Our dedication to innovation and customer satisfaction has earned us a reputation as a trusted provider of abrasive solutions.[News Content]The Diamond Resin Bond Chamfering Wheel has been making waves in the metalworking industry, thanks to its exceptional performance and durability. This cutting-edge abrasive tool, developed and manufactured by our company, has been hailed as a game-changer in metal chamfering applications.The Diamond Resin Bond Chamfering Wheel is engineered to deliver unparalleled cutting power and precision, making it the go-to choice for professionals in the metalworking industry. Its advanced resin bond technology ensures superior bonding strength and wear resistance, allowing for extended use without compromising on performance.One of the key features of the Diamond Resin Bond Chamfering Wheel is its ability to produce smooth and uniform chamfered edges on a wide range of metal materials. Whether it's stainless steel, aluminum, or brass, this innovative abrasive tool consistently delivers impeccable results, making it an indispensable asset for metal fabricators and machinists.Moreover, the Diamond Resin Bond Chamfering Wheel is designed for optimal heat dissipation, preventing overheating and thermal damage during prolonged use. This not only prolongs the lifespan of the abrasive tool but also ensures a consistent and high-quality finish on the workpiece.In addition to its superior performance, the Diamond Resin Bond Chamfering Wheel is also engineered for user convenience and safety. Its ergonomic design and precision-machined construction make it easy to handle and control, reducing operator fatigue and enhancing overall productivity. Furthermore, stringent quality control measures are implemented throughout the manufacturing process to ensure that each chamfering wheel meets the highest standards of safety and performance.The Diamond Resin Bond Chamfering Wheel is available in a variety of specifications and sizes to accommodate different machining requirements. With a versatile range of options, customers can choose the ideal chamfering wheel that meets their specific application needs, further underscoring our commitment to providing tailored solutions for our valued clients.As the demand for high-precision metal components continues to grow, the Diamond Resin Bond Chamfering Wheel represents a significant advancement in abrasive technology. Its ability to deliver exceptional results with efficiency and reliability has positioned it as a top choice for metalworking professionals seeking to elevate their machining capabilities.Our company is proud to be at the forefront of this innovative product, showcasing our ongoing commitment to driving progress in the abrasive tools industry. With the Diamond Resin Bond Chamfering Wheel, we are confident that our customers can achieve greater precision, efficiency, and overall performance in their metalworking operations.In conclusion, the Diamond Resin Bond Chamfering Wheel stands as a testament to our company's dedication to excellence and innovation. It is a reflection of our unwavering commitment to providing cutting-edge abrasive solutions that empower our customers to achieve their machining goals with confidence and ease. We are excited to see the continued impact of the Diamond Resin Bond Chamfering Wheel in the metalworking industry and look forward to further advancements in abrasive technology that will shape the future of manufacturing.