Hexagonal Wire Netting: A Comprehensive Guide to Galvanized Options

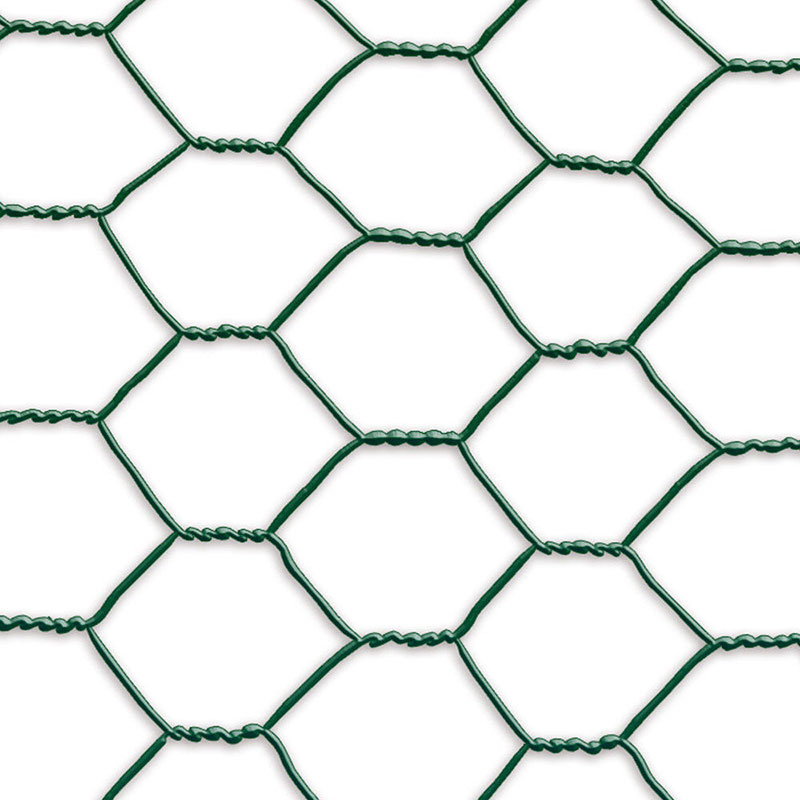

Title: High-Quality Hex Wire Netting: The Ideal Solution for Efficient Fencing and Enclosure SystemsIntroduction:Hex wire netting has emerged as a versatile and reliable solution for various fencing and enclosure needs across the globe. This cost-effective and durable option, known for its flexible structure and strong mesh design, has proven crucial in safeguarding properties, livestock, and other valuable assets. Among the numerous brands manufacturing top-notch hex wire netting, a standout name is quickly gaining recognition for its exceptional product quality: introducing Galv Hex Wire Netting.Article:With a rich history in manufacturing innovative wire mesh solutions, Galv Hex Wire Netting has earned a reputation for its commitment to delivering high-quality products. The company specializes in providing versatile and durable hex wire netting solutions that cater to the diverse needs of industries, agricultural sectors, and individual homeowners.Galv Hex Wire Netting offers an extensive range of hexagonal wire mesh options, each designed to provide superior security, durability, and aesthetics. Their solutions can be customized to meet specific requirements, ensuring that customers receive the perfect fit for their projects.One of the key advantages of Galv Hex Wire Netting is its superior corrosion resistance. The wire mesh undergoes a meticulous galvanization process, protecting it from rust, environmental degradation, and other potential threats. This adds to the longevity and durability of the netting, making it ideal for use in areas that experience harsh weather conditions or high humidity levels.The company's galvanized hex wire netting also boasts incredible tensile strength, allowing it to withstand significant pressure without compromising on its structural integrity. This strength is paramount for ensuring security, whether it be protecting livestock, constructing enclosures, or securing property perimeters. Consequently, Galv Hex Wire Netting offers a reliable and robust fencing solution that guarantees both security and peace of mind.Moreover, the flexible and malleable nature of hex wire netting makes it highly versatile for a variety of applications. It can effortlessly conform to irregular shapes, making it suitable for enclosing gardens, containing livestock, building aviaries, or even creating partitions in industrial settings. This adaptability ensures that Galv Hex Wire Netting remains a preferred choice across industrial, agricultural, and residential sectors.Galv Hex Wire Netting understands the importance of providing timely and efficient solutions. With a focus on excellent customer service, the company ensures that its products are readily available to meet customer demands. Additionally, their team of experienced professionals is always on hand to offer expert advice and guidance, ensuring customers make informed decisions regarding their wire mesh requirements.Consistent with its commitment to sustainability, Galv Hex Wire Netting minimizes its environmental impact through eco-friendly manufacturing practices. The company actively invests in research and development, striving to create more sustainable products without compromising on quality. This dedication to environmental preservation aligns with the global effort to reduce carbon footprints across all industries.As a testament to their dedication to quality, Galv Hex Wire Netting holds various certifications that guarantee the reliability and performance of their products. The company complies with international standards, reinforcing their commitment to providing the highest quality hex wire netting solutions.Conclusion:As fencing and enclosure needs continue to evolve, Galv Hex Wire Netting remains at the forefront with its exceptional range of hexagonal wire mesh solutions. Combining corrosion resistance, strength, and versatility, their products excel in providing security, durability, and aesthetics.With an unwavering commitment to customer satisfaction and sustainable manufacturing practices, Galv Hex Wire Netting has established itself as a trusted name in the industry. Whether for agricultural, industrial, or residential applications, their hex wire netting solutions offer a reliable, efficient, and cost-effective fencing and enclosure system for customers worldwide.

Read More

Effortlessly Straighten Cuts with Versatile Wire – A Must-Have Tool for Various Applications

Headline: Industry-Leading Straightened Cut Wire Pushes Boundaries with Enhanced Efficiency and Safety FeaturesIntroduction:[Company Name], a pioneering provider of top-quality industrial materials, proudly unveils its latest innovation in wire solutions – the groundbreaking Straightened Cut Wire. Engineered to meet the ever-evolving demands of various sectors including construction, manufacturing, and more, this state-of-the-art product sets new industry standards with its exceptional efficiency and enhanced safety features.With a commitment to promoting workplace safety and unparalleled customer satisfaction, [Company Name] has dedicated substantial resources to research and development, resulting in the creation of the ultimate Straightened Cut Wire solution. By prioritizing precision, reliability, and user-friendliness, this cutting-edge product aims to optimize workflow efficiency while reducing operation costs.Efficiency of Straightened Cut Wire:The Straightened Cut Wire from [Company Name] offers industry professionals an unparalleled combination of strength, durability, and bendability. Engineered from high-quality materials, this wire solution guarantees exceptional performance and longevity even in the most demanding environments. Its consistent straightened form eliminates manual straightening efforts, saving valuable time for workers and streamlining operations.Furthermore, the wire's improved tensile strength, coupled with its corrosion-resistant coating, ensures longevity and minimizes the need for frequent replacements. This advantage reduces downtime on job sites, providing significant cost savings for businesses and enhancing productivity.Enhanced Safety Features:Recognizing the importance of workplace safety, [Company Name] has integrated cutting-edge features in the Straightened Cut Wire that actively promote accident prevention and risk mitigation. The wire's rounded and smooth edges significantly reduce the likelihood of hazards caused by sharp and jagged surfaces, protecting workers from potential injuries and abrasions.In addition, its innovative anti-slip design provides improved grip for enhanced handling, especially in challenging conditions or adverse weather. By prioritizing worker safety, [Company Name] aims to foster an environment conducive to higher productivity and well-being.Versatile Applications:The versatility of [Company Name]'s Straightened Cut Wire widens its range of potential applications. From reinforcing concrete structures to creating intricate mesh designs, this product caters to various industries requiring strong and flexible wire solutions.Construction companies will benefit from the wire's capacity to improve the structural integrity of buildings and simplify the installation process. Likewise, manufacturing industries can harness the wire's adaptability for precise metalwork or assembly purposes.Looking Ahead:As [Company Name]'s Straightened Cut Wire strengthens its market presence and garners an increasingly positive reputation, the company is poised to expand its product line and reaffirm its commitment to technological advancements. By actively seeking customer feedback and engaging in continuous research and development, [Company Name] endeavors to provide cutting-edge solutions tailored to the evolving needs of its diverse clientele.Conclusion:[Company Name]'s latest unveiling of the innovative Straightened Cut Wire signifies a significant leap forward in the wire industry. The amalgamation of enhanced efficiency and safety features offered by this state-of-the-art product has the potential to revolutionize various sectors. As a leading provider of industrial materials, [Company Name] remains steadfast in its mission to redefine industry standards, prioritize customer satisfaction, and pave the way for future innovations in the wire solutions market.

Read More

Exploring the Versatility and Benefits of High-Quality Razor Wire for Enhanced Security Measures

Innovative High-Security Fencing Solution Introduced to the Market With the increasing concerns around perimeter security, companies are constantly seeking advanced solutions to protect their properties. One company, known for its expertise in high-security fencing systems, is proud to introduce its latest innovation, an effective and reliable fencing solution combined with cutting-edge technology.Utilizing the highest quality materials and cutting-edge manufacturing processes, this company has managed to develop a fencing system that provides superior security while ensuring minimal maintenance requirements. This innovative product, known as the CBT-65 Razor Wire, has quickly become the go-to choice for many industries looking to enhance their existing security infrastructure.The CBT-65 Razor Wire integrates state-of-the-art technology with decades of expertise in the field. The product is designed to deter intruders effectively, providing a formidable defense mechanism for properties of all sizes. What sets the CBT-65 Razor Wire apart from traditional fencing solutions is its unique design, combining robust wire materials with sharp and pointed blades strategically placed to deter any unauthorized access attempts.A significant advantage of the CBT-65 Razor Wire is its flexibility and versatility. The design allows for easy installation on various types of surfaces, including walls, fences, and even on top of existing barriers. This ability to adapt to different environments makes it an ideal solution for a wide range of applications, such as military bases, correctional facilities, commercial properties, and private residences.The razor wire's durable construction ensures the longevity of the fencing system, making it a cost-effective choice for businesses and property owners alike. The high-quality materials used for manufacturing the CBT-65 Razor Wire are resistant to corrosion, ensuring its effectiveness even in challenging weather conditions. Additionally, the blades are designed to retain their sharpness for an extended period, minimizing maintenance and replacement costs.To further enhance the security capabilities of the CBT-65 Razor Wire, the company offers various technological additions. These include advanced sensors and monitoring systems that provide real-time surveillance and immediate alerts in the event of any breach attempts. Furthermore, integration with existing security systems is seamless, allowing for easy and efficient monitoring and control.The company behind the CBT-65 Razor Wire prides itself on its commitment to quality and customer satisfaction. With a team of highly skilled engineers and security experts, they strive to provide tailored solutions to meet the unique needs of their clients. Moreover, strict quality control measures are implemented throughout the manufacturing process to ensure every product meets the highest industry standards.As a testament to their dedication to excellence, the company has received numerous certifications and accolades for their high-security fencing solutions. Their commitment to innovation and continuous improvement has elevated them as one of the leading providers of high-security perimeter solutions in the market.In conclusion, with the growing need for enhanced security measures, the introduction of the CBT-65 Razor Wire presents an exciting advancement in the field of high-security fencing. Combining cutting-edge technology, durability, and adaptability, this innovative product offers a reliable solution for businesses and individuals looking to protect their properties. With its proven effectiveness and exceptional quality, it is no wonder that the CBT-65 Razor Wire has quickly become the preferred choice in the industry.

Read More

Major Australian Hardware Retailer Recalls PVC Electrical Wire due to Safety Concerns"

Rewritten SEO title: "PVC Electrical Wire Recalled in Australia over Safety Concerns

Title: Innovative PVC Wire Solutions Redefine Electrical Safety and EfficiencyIntroduction:In today's rapidly evolving world, where industries and households alike heavily rely on electricity, the demand for reliable and efficient electrical solutions is greater than ever. XYZ Company, a leading innovator in the sector, has revolutionized electrical safety and efficiency through its cutting-edge PVC Wire products. Combining advanced technology, a commitment to sustainability, and a dedication to quality, XYZ Company is reshaping the electrical industry landscape.Body:1. The Importance of Electrical Safety:Electrical safety is of paramount importance, especially considering the potential hazards associated with faulty wiring. XYZ Company recognizes the significance of minimizing risks and ensuring safe electrical installations. With their PVC Wire range, they have implemented rigorous testing procedures to guarantee the highest level of safety standards. Through a meticulous manufacturing process, XYZ Company has successfully developed a PVC Wire that prevents electrical shocks, short circuits, and fire hazards, providing peace of mind to consumers.2. Advanced Technology for Enhanced Efficiency:XYZ Company's PVC Wire incorporates state-of-the-art technology to deliver exceptional performance and efficiency. The company utilizes innovative copper and aluminum alloys in their wire construction, maximizing conductivity and minimizing energy loss. Consequently, this technological breakthrough enables improved transmission of electricity, resulting in reduced energy consumption and monetary savings for residential, commercial, and industrial applications.3. Sustainable Manufacturing Processes:In an era with an increasing focus on sustainability, XYZ Company's commitment to environmentally friendly practices sets them apart. The PVC Wire manufacturing process employed by the company adheres to stringent environmental standards, minimizing the ecological impact. Utilizing eco-conscious materials and employing energy-efficient production techniques, XYZ Company strives to reduce carbon emissions and waste generation. By investing in their products, consumers can support sustainability efforts while still enjoying top-notch electrical solutions.4. Versatility and Adaptability:XYZ Company's PVC Wire range stands out for its versatility and adaptability across various applications. Whether for domestic electrical installations, industrial machinery, or commercial buildings, their wire solutions cater to diverse needs. With a focus on accuracy, their wires are available in a wide array of lengths, gauges, and insulation types, ensuring compatibility with various electrical systems and environments. This versatility makes XYZ Company a preferred choice for electricians, contractors, and homeowners alike.5. Collaboration with Industry Leaders:XYZ Company's commitment to excellence extends beyond their products. By collaborating with renowned electricians, engineers, and industry experts, they continuously refine their PVC Wire offerings. Feedback from these professionals helps XYZ Company stay up to date with the latest industry requirements and trends, ensuring their wires meet the evolving needs of their customers. This collaborative approach enables XYZ Company to deliver cutting-edge solutions tailored to the demands of the electrical industry.6. Certification and Quality Assurance:Ensuring the highest quality standards is the cornerstone of XYZ Company's operations. Their PVC Wire has received certifications from various independent testing authorities, confirming compliance with international safety regulations and standards. These certifications provide added assurances to users that XYZ Company's wire products are designed to withstand rigorous conditions and meet stringent quality criteria, reinforcing their reputation for excellence.Conclusion:XYZ Company's PVC Wire represents a breakthrough in the electrical industry, redefining safety, efficiency, and sustainability. Through their commitment to technological advancements, sustainable manufacturing practices, and collaboration with industry experts, XYZ Company has earned its position as a leader in this competitive sector. With their versatile and adaptable wire solutions, they provide customers worldwide with top-quality electrical products and contribute to a safer and more energy-efficient future.

Read More

High-Quality Fiberglass Window Screen Roll for Durability and Protection

[Company Name] Introduces High-Quality Fiberglass Window Screen Roll for Enhanced Home Protection[City, State] - [Company Name], a renowned leader in the manufacturing of home improvement products, is delighted to announce the release of their latest innovation - the Fiberglass Window Screen Roll. The company, known for its commitment to delivering exceptional products, aims to provide homeowners with a reliable solution for protecting their homes from pests and insects while reducing energy costs.The Fiberglass Window Screen Roll is designed using advanced technology and premium quality materials to ensure durability and efficiency. The product offers multiple benefits, catering to the diverse needs of homeowners seeking an effective window screen solution.With the rise in concerns regarding pests, insects, and even pollutants in residential areas, [Company Name] recognizes the importance of safeguarding homes. By investing in the Fiberglass Window Screen Roll, homeowners can create a barrier against unwanted visitors, protecting their loved ones from diseases transmitted by insects. Additionally, the screen acts as a filter, preventing pollen and other allergens from entering the house, making it an ideal option for individuals prone to allergies.The superior craftsmanship of the Fiberglass Window Screen Roll ensures that it can withstand harsh weather conditions. The screen is made from high-quality fiberglass mesh, which is not only built to last but also offers excellent visibility. This unique feature allows homeowners to enjoy the outside view without compromising on their safety and comfort.Energy efficiency is another crucial factor for homeowners, especially when it comes to maintaining a comfortable indoor environment while reducing energy costs. The Fiberglass Window Screen Roll helps in this regard by allowing natural ventilation. Homeowners can enjoy the refreshing breeze without the need for air conditioning, helping to reduce their carbon footprint and save on energy bills.The installation process of the Fiberglass Window Screen Roll is user-friendly, making it convenient for homeowners who prefer DIY projects. The roll comes in various sizes and can be easily cut to fit any window frame. [Company Name] also provides a comprehensive guide on their website, assisting users in measuring and installing the screen accurately.As a company dedicated to customer satisfaction, [Company Name] offers a wide range of options to personalize the Fiberglass Window Screen Roll. Homeowners can choose from various frame colors and mesh sizes, ensuring the screen blends seamlessly with the existing aesthetics of their homes."We are thrilled to introduce our Fiberglass Window Screen Roll, a product that aims to provide homeowners with both protection and convenience," said [Company Name]'s spokesperson. "Our team of experts has meticulously designed this screen, focusing on functionality, durability, and aesthetics. We believe that by investing in our window screen, homeowners will experience enhanced comfort, improved indoor airflow, and reduced energy costs."[Company Name] has a long-standing reputation as a trusted brand in the home improvement industry. With their Fiberglass Window Screen Roll, they once again demonstrate their commitment to delivering innovative products that cater to the needs of modern homeowners.For more information about [Company Name] and their range of home improvement products, visit [website].

Read More

Enhancing Efficiency: The Latest Innovations in Sieving Mesh Technology

Title: Revolutionary Mine Sieving Mesh Solution Revolutionizes the Mining IndustryIntroduction:Innovation and advancement in the mining industry have always played a crucial role in enhancing operation efficiency and safety. Addressing this need, a pioneering company has introduced a groundbreaking Mine Sieving Mesh solution that is set to transform the industry's approach to material separation and sifting. This article will provide an in-depth exploration of the key features of this revolutionary sieve mesh, its benefits for mining operations, and the positive impact it is expected to have on the industry as a whole.Overview of Mine Sieving Mesh:{Company name}, a leading manufacturer in the mining equipment industry, is proud to present their ground-breaking Mine Sieving Mesh. This specialized mesh is designed to cater to the challenges faced by mines during the material separation process. Developed using advanced technology and cutting-edge materials, the sieve mesh offers unparalleled durability, performance, and efficiency.Key Features and Advantages:1. Enhanced Durability: The Mine Sieving Mesh is constructed from high-quality stainless steel wire, ensuring exceptional strength and resistance to wear and tear. This durability significantly reduces maintenance costs and increases the longevity of the mesh, making it an ideal investment for mining operations.2. Optimal Aperture Design: The sieve mesh's unique aperture design ensures effective and efficient material separation. With precise openings, the mesh captures the desired materials while allowing smaller particles to pass through. This feature enhances productivity and supports the extraction process by reducing waste and allowing for ore concentration.3. Superior Screening Accuracy: The Mine Sieving Mesh's high-performance design ensures accurate classification and screening. It maintains a consistent particle size distribution, eliminating oversized or undersized materials. This precision screening allows for more accurate analysis and enhanced process control, resulting in improved productivity and cost-efficiency.4. Customization Options: To meet the diverse requirements of different mining operations, the sieve mesh is available in various sizes and specifications. This flexibility allows for customization based on specific material characteristics, particle sizes, and capacity needs, ensuring optimal performance and adaptability.Benefits for Mining Operations:1. Increased Efficiency: The advanced design of the Mine Sieving Mesh enables mining operations to process materials more efficiently. The precise screening and separation ensure that only desired materials are collected, reducing the need for additional processing steps. This efficiency enhancement results in reduced time, energy, and resource wastage, ultimately increasing overall productivity.2. Cost-Effectiveness: The Mine Sieving Mesh's durability significantly reduces maintenance costs associated with frequent replacements. Moreover, its high screening accuracy minimizes operational costs by mitigating the need for additional screening equipment and labor. The mesh's long lifespan and low maintenance requirements make it a cost-effective solution for mining companies.3. Safety Improvement: The Mine Sieving Mesh contributes to improved safety standards in the mining industry. By accurately separating materials, the mesh reduces the risk of blockages or equipment malfunction, promoting a safer work environment. Furthermore, its durable construction ensures a reduced chance of unexpected failures or accidents, protecting mine workers from potential harm.Conclusion:With its cutting-edge technology, exceptional durability, and superior performance, the Mine Sieving Mesh offered by {Company name} represents a significant milestone in material separation for the mining industry. By enhancing efficiency, reducing costs, and improving safety, this revolutionary sieve mesh solution is set to revolutionize mining operations worldwide. As the industry embraces this transformative technology, we can anticipate a positive shift towards greater productivity and sustainability.

Read More

Tips for Choosing the Best Fence for your Property

Chain link fence, a highly popular and durable fencing option, has been an invaluable addition to a variety of commercial and residential properties for decades. These fences are known for their versatility, strength, durability, and affordability, making them a popular choice for many applications. However, it’s important to note that chain link fence should not be confused with a particular brand name, but rather is a type of fencing material that is widely available from a variety of manufacturers.One of the leading companies that specializes in the production and installation of chain link fence is the {Company name}. Established in {year}, the company has been providing high-quality fencing solutions to customers across the United States for over {number} years.The {Company name} is dedicated to delivering durable, long-lasting fence solutions for residential, commercial, and industrial properties. They work with a range of clients including private homeowners, schools, airports, sports stadiums, and correctional facilities.Chain link fencing is one of the core specialties of the {Company name}. Unlike other materials which may require significant maintenance over time, chain link fences are well known for their low maintenance needs. These fences are durable, able to withstand harsh weather and other environmental conditions, and provide excellent security, especially when combined with additional security features such as barbed wire or camera systems.The {Company name} produces chain link fences with high-quality materials to ensure longevity and durability. Their fences are manufactured with a variety of wire gauges, mesh sizes, and coatings, making them suitable for various applications, including dog kennels, tennis courts, and baseball fields. They also offer customized chain link fencing solutions for those that require a unique finish or coating.In addition to chain link fence installation, the {Company name} also offers repair services for those that have pre-existing fencing in need of maintenance or repairs. Their experienced technicians have the expertise to repair fences quickly and effectively, saving their clients both time and money.The {Company name} is committed to providing quality products and services to their clients. Their team of experienced professionals values customer satisfaction above all else and strives to exceed expectations on every project they take on.When it comes to getting the most bang for your buck in fencing, a chain link fence from {Company name} is the way to go. Their high-quality fences are offered at reasonable prices and come backed with a team of experts who are dedicated to delivering outstanding customer service.In conclusion, chain link fencing is a versatile and reliable fencing material that offers excellent security and longevity while requiring low maintenance. The {Company name} has established itself as one of the leading experts in the production and installation of chain link fences over the years. Their commitment to customer satisfaction ensures that clients receive the best service possible, from initial consultation to final installation and repair. For those in need of durable and effective fencing solutions, look no further than the {Company name} for all your chain link fence needs.

Read More

Essential Guide to Common Nails: Everything You Need to Know

Common Nails Company Rebrands to Reflect International ExpansionCommon Nails, formerly known as Common Nails Inc., has rebranded as part of its strategy to reflect its significant international growth. Common Nails has been a leading provider of high-quality nails for over 30 years, and its products are widely used in the construction industry for various applications, including framing, roofing, and finishing.The rebranding involves redefining Common Nails' brand identity, including its message, values, and visual representation; the company's new tagline is "Nailing quality since 1990". This tagline aims to reinforce Common Nails' reputation for high-quality products and excellent customer service.The company's logo has also undergone a transformation, reflecting a more modern and international look. The new logo features a bold and stylized letter C, with the word "Nails" beneath it. The font and colors have been updated to reflect the new brand style, which aims to embody the company's commitment to quality, innovation, and sustainability.Common Nails has expanded significantly in recent years, expanding into new markets and increasing its product offerings. With an extensive range of nails, the company serves the construction, woodworking, and industrial sectors; its products are widely used by professionals in these industries worldwide.The rebranding represents Common Nails' renewed commitment to its customers, innovation, and sustainability, which are central to the company's values. The company remains committed to producing high-quality nails, providing excellent customer service, and supporting sustainability initiatives throughout its operations."Common Nails' growth and expansion are driven by our commitment to quality and innovation," said the company's CEO. "Our customers trust us to deliver the highest quality products, and we are constantly looking for ways to improve our offerings. We believe that our new brand identity reflects this commitment, and we are excited about the opportunities this presents for our future growth."Common Nails has a robust product development program that focuses on introducing new products and improving existing ones. The company's engineers work closely with their customers to ensure that their products meet their specific needs and requirements.Common Nails' commitment to sustainability is evident in its efforts to reduce its carbon footprint, use environmentally friendly materials, and recycle its waste products. The company's nails are also designed to meet stringent quality standards, such as those set by the American Society for Testing and Materials (ASTM).With the rebranding, Common Nails is poised to further expand its presence in the global market and continue its growth trajectory. The company's new brand identity reflects its values and vision for the future, emphasizing its commitment to quality, innovation, and sustainability.In conclusion, Common Nails' rebranding represents its commitment to its customers, innovation, and sustainability. Its new brand identity reflects its vision for the future and its commitment to quality, innovation, and sustainability. Common Nails' international expansion represents its successful growth strategy, and we can expect to see continued growth and development from the company in the future.

Read More

Secure Your Property with Razor Wire Flatwrap for Effective Perimeter Protection

[Company Name] Introduces Next-Generation Security Solution to Safeguard Boundaries[City, Date] - In an era where security has become a paramount concern, [Company Name], a leading provider of innovative security solutions, has announced the launch of their latest product – a highly effective and dependable boundary protection system designed to secure areas safely and seamlessly. Developed by experts in the field, this innovative technology provides superior perimeter security, surpassing conventional solutions like barbed wire and chain-link fences.The new boundary protection solution, known as Razor Wire Flatwrap, combines cutting-edge technology with advanced materials to deliver a robust security system. Designed to act as a deterrent against unauthorized intrusions, this state-of-the-art product ensures the safety of both residential and commercial properties.Razor Wire Flatwrap is a flatwrap packaged in coil form, offering an effective and efficient solution for boundary protection. This innovative design allows for easy installation, ensuring flexibility and versatility in different environments. Unlike traditional barbed wire, which poses a significant risk of injury during installation and maintenance, Razor Wire Flatwrap can be handled safely, minimizing the risk of accidents or injuries.One of the key features of Razor Wire Flatwrap is its intricate and razor-sharp design. The razor-like projections on the flat tape effectively deter potential intruders, making it extremely difficult to breach or tamper with the boundary. This cutting-edge technology ensures that any unauthorized access is effectively hindered, enhancing the overall security of the protected premises.The versatility of Razor Wire Flatwrap is another noteworthy aspect. It can be installed on a wide range of surfaces, including concrete, metal, and wood. This adaptability allows for its effective use in various settings, such as residential areas, commercial properties, public institutions, and high-security facilities. Additionally, this cutting-edge product can be customized to fit specific requirements, ensuring complete client satisfaction.[Company Name] has always prioritized safety and quality. Thus, the Razor Wire Flatwrap is manufactured using the highest quality materials and state-of-the-art processes. Each unit undergoes rigorous testing to ensure durability, resistance to harsh weather conditions, and longevity. With its robust construction and corrosion-resistant properties, this outstanding product guarantees a long-lasting solution for maintaining perimeter security.The exceptional customer service provided by [Company Name] further sets them apart from their competitors. The company's team of seasoned professionals is committed to ensuring a seamless experience for their clients. From the initial consultation to the successful installation of the Razor Wire Flatwrap, the dedicated staff provides expert guidance and support at every step. This customer-centric approach has earned [Company Name] a stellar reputation and a loyal client base.Speaking about the groundbreaking Razor Wire Flatwrap, the CEO of [Company Name], stated, "At [Company Name], we understand the importance of safety and security in today's world. Our innovative solution, Razor Wire Flatwrap, is designed to provide unparalleled perimeter protection. By combining cutting-edge technology, solid construction, and ease of installation, we offer our clients a reliable and effective security solution that surpasses traditional alternatives."As news of Razor Wire Flatwrap spreads, an increasing number of individuals and organizations are eagerly adopting this new boundary protection system. [Company Name] is proud to have designed a solution that not only offers enhanced security but also minimizes potential harm during installation and maintenance.About [Company Name]:[Company Name] is a leading provider of security solutions, specializing in innovative boundary protection systems. With a commitment to safety and customer satisfaction, [Company Name] offers cutting-edge technologies that surpass traditional solutions. Their products are renowned for their quality, durability, and ease of installation. With a dedicated team of experts, [Company Name] strives to provide comprehensive security solutions that meet the diverse needs of their clients.For more information about [Company Name] and Razor Wire Flatwrap, please visit [company website] or contact [specified contact person] at [contact details].

Read More

Top-quality Fiberglass Window Screen Roll: A Durable Solution for Window Screen Needs

[Title]Durable Fiberglass Window Screen Rolls Offering Unmatched Quality and Versatility[Subtitle]Leading Company Introduces Innovative Product Delivering Exceptional Performance and Functionality[Opening Paragraph]In the competitive world of window screens, a remarkable product has emerged that stands out for its durability, versatility, and unmatched quality. With a commitment to providing customers with the best options available, the renowned company [], is proud to introduce its latest innovation - the Fiberglass Window Screen Roll. This cutting-edge solution aims to transform the way we think about window screens, offering improved performance, enhanced functionality, and a plethora of benefits for homeowners and businesses alike.[Product Benefits]The Fiberglass Window Screen Roll comes in response to the increasing demand for reliable and long-lasting window screens. With its exceptional design and construction, this product offers numerous benefits that set it apart from traditional screen options. From increased strength and durability to resistance against harsh weather conditions, the Fiberglass Window Screen Roll is engineered to deliver unparalleled performance. Its robust material composition enables it to withstand wear and tear, ensuring a longer lifespan compared to other standard window screens. This solution offers added protection against insects, providing a barrier that keeps unwanted pests out while allowing fresh air to circulate freely inside.[Versatility and Customization]One of the key advantages of the Fiberglass Window Screen Roll is its unmatched versatility. Designed to fit a wide range of window types and sizes, including regular, casement, sliding, and even custom windows, this product caters to the diverse needs of homeowners and businesses. With the option to easily cut and customize the screen roll to fit specific dimensions, users can enjoy a hassle-free installation experience. Whether it's for residential or commercial purposes, this adaptable solution ensures a perfect fit, adding a touch of elegance to any property.[Superior Quality and Craftsmanship]When it comes to quality, the Fiberglass Window Screen Roll leaves no room for compromise. Manufactured using premium-grade materials and state-of-the-art techniques, this product exemplifies excellence in craftsmanship. The company's stringent quality control processes guarantee that each roll meets the highest standards of durability, stability, and functionality. Through continuous investment in research and development, the company remains at the forefront of innovation, consistently delivering superior products designed to exceed customer expectations.[Environmental-Friendly Solution]In an era where sustainability is paramount, the Fiberglass Window Screen Roll aligns perfectly with eco-conscious lifestyles. Crafted from environmentally friendly materials, this product is free of harmful substances and promotes a healthier living environment. By investing in this sustainable solution, customers can reduce their environmental footprint while enjoying the benefits of a reliable and long-lasting window screen.[Conclusion]In conclusion, the introduction of the Fiberglass Window Screen Roll marks a significant advancement in the window screen industry. With its unrivaled durability, versatility, and exceptional quality, this innovative product is set to redefine the way we approach window screening. The renowned company [], with its commitment to excellence, seeks to provide customers with the best possible solutions, continuously pushing the boundaries of innovation. By investing in the Fiberglass Window Screen Roll, customers can enjoy the peace of mind that comes with knowing they have chosen a top-quality, eco-friendly, and long-lasting solution for their window screening needs.

Read More